Description & Background

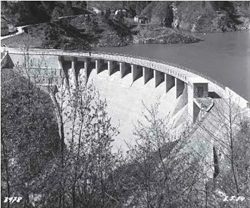

Palagnedra Dam was constructed between 1950 and 1952 on the Melezza River located in the country of Switzerland. Palagnedra Dam is a 72-meter tall, 120-meter long, concrete gravity arch dam, primarily constructed for hydropower. The Palagnedra Dam was the final phase of the Maggia hydroelectric scheme, which would eventually act as a compensation reservoir for the Verbano I and II plants, both of which are located on the Melezza River.

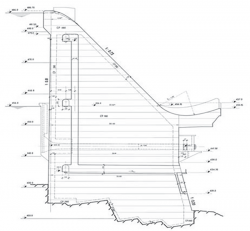

The dam consists of two parts: The arch-gravity section and a 45-meter high, 87-meter long, and 3-meter thick diaphragm wall. The spillway prior to the dam incident consisted of 13 openings, each 5 meters wide and 3 meters tall separated by piers that supported a road bridge that crossed the dam. The dam design spillway capacity was approximately 450 cubic meters per second. The dam impounds approximately 4.8 million cubic meters of water at the top of the dam and upon its completion provided approximately 40 percent of the electricity to the surrounding areas of the Melezza River basin.

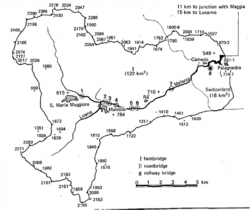

The dam has a drainage area of 140 square kilometers, which at the time consisted of 52 percent afforested land and 48 percent bare rock, all of which discharged into the Melezza river. Between 1901 and 1977, the mean annual precipitation at Camedo was approximately 2509 millimeters, with the maximum recorded annual accumulated precipitation during this time frame being approximately 4021 millimeters. The mean discharge of the Melezza River at the Camedo was 6.3 cubic meters per second and the minimum was less than 1 cubic meter per second. By 1978, the maximum spillway capacity for the lake was exceeded on six separate occasions. It was observed early on after the completion of the structure that the banks of the Melezza River and many of its tributaries were very thin and highly erodible. This would become one of the major issues with the long-term productivity of the facility due to large quantities of sediment being deposited into the reservoir during every major flood event.

Shortly after the dam was completed in 1953, a plan was developed to manage the large quantities of sediment being deposited into the reservoir by the Melezza River. This plan was to preserve the storage capacity of the reservoir, and to protect the bottom outlet and water intake by continuously pumping the alluvial sediment over the dam crest to the downstream Melezza riverbed from 1968 and 1973. However, due to the negative environmental impact of pumping the sediment downstream, pumping was discontinued in 1973. As an alternative to the constant pumping, an intermediate submerged dam and diversion tunnel were constructed upstream of the concrete gravity arched dam. The diversion tunnel was 1.7 kilometers long with a diameter of approximately 6.3 meters and a maximum flow capacity of 300 cubic meters per second. This new diversion tunnel allowed for inflow upstream of the newly constructed and submerged dam to be diverted directly downstream, bypassing the arched gravity dam and hydro facilities.

Photo of debris accumulation at the spillway during the flood event. (Photo Source: Swiss Dams, 2017)

On August 7, 1978, flood waters ravaged down the Melezza River claiming the lives of 24 people upstream of the facility and causing significant damage to the Palagnedra Dam. During the early part of the storm, the diversion tunnel was gradually opened to help bypass the incoming flow. Between 4:15 PM and 6:15 PM, the tunnel had to be gradually closed at the request of the local police station due to the increasing river elevation which was occurring downstream of the facility. The hope was that by closing the tunnel it would delay the flooding of a campground located about 10 kilometers downstream.

Upstream of the dam, large quantities of sediment and woody debris continued to flood into the reservoir. It is estimated that approximately 25,000 cubic meters of wooden debris and logs engulfed Palagnedra Lake, blocking the 13 spillway openings and causing complete overtopping of Palagnedra Dam. The upstream dam and diversion tunnel became inoperable due to approximately 1.8 million cubic meters of silt, sand, and gravel covering the diversion tunnel with a 12- to 14-meter-thick layer of sediment. The grating of the water intake was partially destroyed, blocking the 7.5 kilometer long and 3.75-meter diameter bypass tunnel for the hydroelectric plant. With all the methods for bypassing the flow inoperable, flow overtopping the right abutment quickly eroded away the earthen backfill exposing the concrete core and causing severe damage to the structure.

With the situation continuing to progress, steps toward eliminating the immediate threat and improving the safety of the dam began on August 8, 1978, just one day after peak the flooding. The first step taken was to secure the stability of the concrete core wall where the backfill had eroded away until permanent repairs could be made. The second step was to reduce the level of the reservoir. This occurred over three separate instances with the first being a 10-meter drawdown, then another 7 meters, and ultimately another 8 meters. A permanent surveillance program was implemented to detect any possible infiltration of water or cracks in the diaphragm wall and the adjacent terrain. Lastly, debris was cleared from the inlet of the diversion tunnel and both upstream and downstream reservoir. Once the diversion tunnel was cleared, much of the sediment was flushed from the upstream reservoir via the diversion tunnel. Inflow from the upstream Melezza River was diverted for an additional year until May 31, 1979. Once an assessment of the damages caused by the flooding was able to be thoroughly conducted, it was evident that the damage at the facility were both extensive and expensive.

Erosion at the bottom of the bypass channel. (Photo Source: C.Auel, 1982)

In the aftermath of the incident, a supporting buttress was constructed against the diaphragm wall to help with stability after the massive erosion that occurred in that area during flooding. Following the completion of the diaphragm wall buttress, the dam reservoir was cleared of sediment and debris. Clearing of the debris occurred in two phases, Phase I included the removal of the 25,000 cubic meters of logs and woody debris which had accumulated in the lake during the flood event. Only a small portion of this debris was manually removed, the majority was burned on site. Phase II of the clean-up process was the pumping of 300 liters per second of sediment from the lakebed over a four-and-a-half-month period. Pumping was complete in December 1978, approximately 300,000 cubic meters of sediment was removed from the reservoir via pumping.

With the lakebed clear of debris and excess sediment, the low-level outlet for the project was once again operational allowing for the 1 to 1.5 cubic meters per second base flow from the Melezza River to be diverted through the bypass during the additional remedial work remaining at the project. Incoming flow and heavy machinery were used to flush an additional 2.1 million cubic meters of sediment from the lakebed over the course of the 3-month period from January to March 1979.

Due to the high concentration of suspended solids in the inflow from the Melezza River, extensive abrasive damage occurred to the bottom of the upstream diversion tunnel. Significant spillway upgrades to the project resulted as part of the incident response which included:

- Swiss Authority responsible for the security of large dams requested that the spillway be redesigned to take into consideration the 37 annual flood records in the Melezza River. The new spillway would have a capacity of 2200 cubic meters per second (nearly five times its original capacity).

- A new bridge with a 60-meter span was constructed approximately 25 meters downstream of the site to allow passage across the valley. This allowed for the existing bridge located on top of the dam to be removed and for the previous spillway with 13 openings to be converted into an unbroken 80-meter outlet.

- The ski jump or flip bucket was modified to accommodate the higher design flow.

Although no formal dam safety regulations were developed, the dam incident was one that resulted in significant regulatory changes within the Swiss National Dam Safety Authority which included the implementation of new requirements for spillway capacity and debris movement for all dams. Scale models were developed to study the behaviors of woody debris in floods. In general, it was determined that in alpine conditions, trees are quickly broken up and shortened to smaller lengths. Because of these findings, dams located on larger rivers and at lower elevations were expected to have larger openings. In contrast, smaller openings were more acceptable at facilities located in the high elevations of the Alps on smaller streams.

In 2002, the first written dam safety guidelines were published in Switzerland; however, they did not contain any specified design criteria. In 2017, updated guidelines were developed with a working group of major dam owners. These guidelines would include explicit values and clear criteria for spillway capacity requirements and debris movement.

References:

(1) Baumer, A. & Martinoli, T. (n.d.). Palagnedra Info Sheet. Swiss Committee on Dams.

(2) U.M. (1996). Silting problems in the Palagnedra Reservoir, Maggia power plants. International Symposium 1996 in Zurich.

(3) Vischer, D. (1981). Silting up of Impoundments And Reservoirs in the Alpine Region, Messages (No 53). The Research Institute for Hydraulic Engineering, Hydrology and Glaciology.

(4) Brushin, J. (1982). The overtopping of the Palagnedra dam. International Water Power & Dam Construction. 34(1).

This case study summary was peer-reviewed by Alon Dominitz, P.E., New York Dam Safety.

Summary

Photos

- Overhead View of the Dam and Bridge – Post Repairs. (Photo Source: Swiss Committee on Dams)

- Debris accumulation during the flood event.

- Typical cross-section of the Palagnedra Dam. (Photo Source: Swiss Committee on Dams)

- Photo of debris accumulation at the spillway during the flood event. (Photo Source: Swiss Committee on Dams, 2017)

- Erosion at the bottom of the bypass channel. (Photo Source: C.Auel, 1982)

- Melezza Catchment Area with elevation. (Photo Source: J. Bruschin, 1982)

- Old Concrete spillway of the Palagnedra Dam. (Photo Source: Ofima, 1954)

- Present day photo of the Palagnedra Dam. (Photo Source: A Dominitz, 2018)

- Present day photo of the Palagnedra Dam. (Photo Source: A.Dominitz, 2018)

Videos

- Sediment Removal Techniques for Reservoir Sustainability

- Diga di Palagnedra – Drone View

- 2013 Emptying of Palagnedra

- ASDSO Webinar: Hydrologic Hazards: Estimating Probabilities of Extreme Floods

- ASDSO Webinar: Rainfall and Dam Safety-From PMP to the 100-Year Storm

Lessons Learned

All dams need an operable means of drawing down the reservoir.

Concrete-lined spillways are vulnerable to significant damage and potential reservoir breach if flows are not safely contained within the conveyance structure.

Dam incidents and failures can fundamentally be attributed to human factors.

Floods can occur due to unusual or changing hydrologic conditions.

High and significant hazard dams should be designed to pass an appropriate design flood. Dams constructed prior to the availability of extreme rainfall data should be assessed to make sure they have adequate spillway capacity.

Additional Lessons Learned (Not Yet Developed)

- Historical data should always be considered in the design. Prior to the 1978 flood event, the maximum spillway capacity for the project had been exceeded on at least six (6) separate occasions.

- There should also be a clear understanding of the hydraulics of the project and potential flood impact downstream prior to the implementation of new construction.

- Even good intentions may have unintended consequences. In the case of the bypass tunnel, excess scouring in the tunnel during the flood event and the contribution of bypass flows to flooding downstream resulted in the bypass tunnel being closed.

Other Resources

Reservoir Debris Management

Author: Caroline Ubing, Shannon Monahan, and Sean Kimbrel

Research and Development Office Science and Technology Program (Final Report) ST-2016-4781 SRH-2016-37

Federal Guidelines for Inundation Mapping of Flood Risks Associated with Dam Incidents and Failures

Author: Federal Emergency Management Agency

Selecting and Accommodating Inflow Design Floods for Dams

Author: Federal Energy Regulatory Commission

Selecting Analytic Tools for Concrete Dams to Address Key Events Along Potential Failure Mode Paths

Author: FEMA

FEMA P-1016

Photographs of the Incident at Palagnedra

Author: P. Bonzani

Reservoir Sedimentation

Author: Sedimentation and River Hydraulics Section Hydrology Branch

Technical Guidelines for Bureau of Reclamation

Floating Debris at Reservoir Dam Spillway

Author: Swiss Committee on Dams

Report of the Swiss Committee on Dams on the state of floating debris issues at dam spillways