Feijão Dam B-1 (Brazil, 2019)

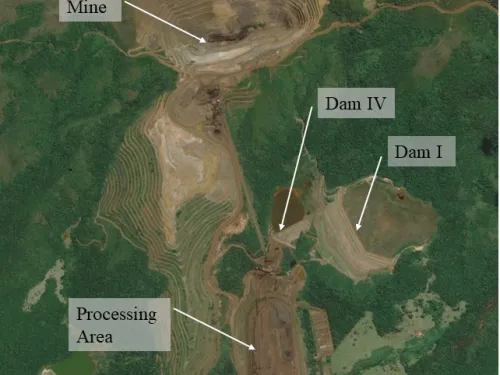

Dam B-1 was a tailings storage facility at the Córrego do Feijão iron ore mine near the city of Brumadinho in the state of Minas Gerais in southeastern Brazil. The mine, including Dam B-1, was owned and developed by Ferteco until 2001, when Vale S. A. acquired Ferteco. The dam was developed to store and dewater sluiced iron ore tailings.

Background

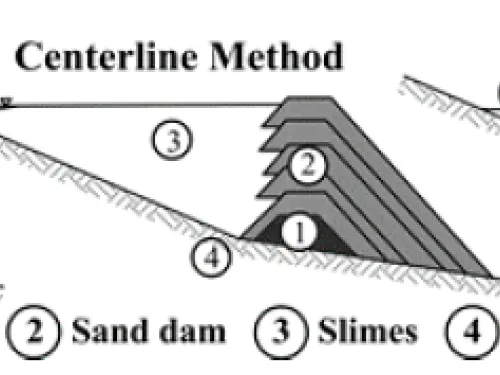

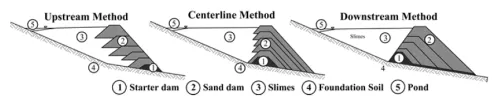

Mine tailings are the waste result of mining and processing minerals. The tailings are typically a mixture of sand, silt, metals, chemicals, and water; they can be solid, liquid, or a slurry of fine particles, and are often toxic, caustic and potentially radioactive. Tailings are usually discharged as a slurry to a tailings storage facility such as a tailings dam. Tailings dams are typically constructed with a starter dike sized to impound the initial two or three years of tailings plus accommodation for storm storage. Over time, the dike is raised with the rising elevation of deposited tailings. Tailings dams are generally constructed using one of three methods: upstream, downstream, or centerline, which refers to the direction the crest moves in relation to the initial starter dike as the dam is raised. In the upstream method, a starter dike is constructed, then tailings are discharged from its crest to form a beach. The beach then becomes the foundation for a second perimeter dike, and the process continues with subsequent embankment raising moving upstream. In the downstream method, tailings are initially discharged behind a starter dike. The dike embankment is raised by placing fill on the downstream side of the embankment. In the centerline method, a starter dike is constructed, and tailings are discharged from the dike crest to form a beach. The embankment is raised by placing fill on the beach and the downstream slope of the embankment simultaneously. The upstream method is generally the least costly, but provides the least stability. Upstream constructed tailings dams are more prone to failure than dams constructed using the downstream method.

Construction History

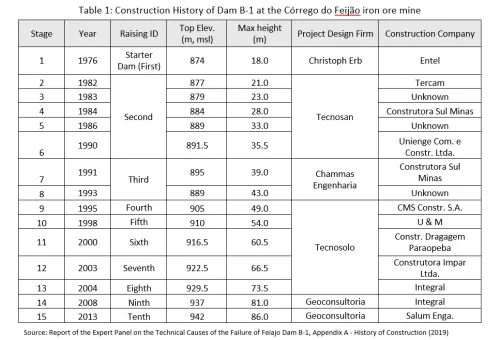

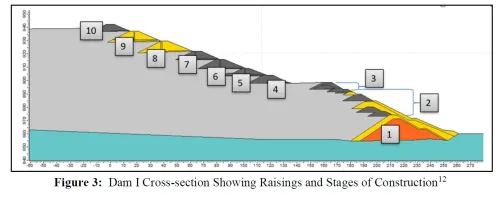

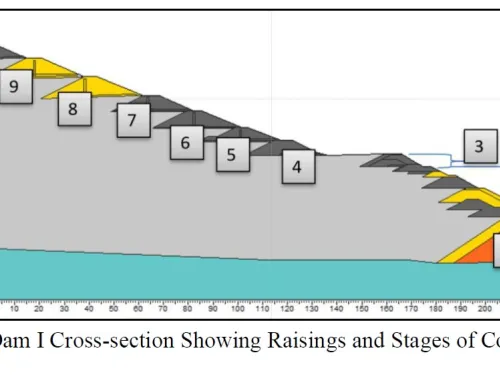

Dam B-1 was constructed using the upstream construction method over a period of 37 years from 1976 to 2013 in 10 raises. No new raisings were constructed after 2013, and tailings disposal ceased in July 2016. The dam reached a maximum height of 86 m (282 ft) and a crest length of 720 m (2,632 ft). The stored tailings covered an area of 249,500 m2 and had a total volume of 12.37 million m3. The timeline of dam raisings is shown in the table below.

The material used to construct the dam was generally obtained from the tailings targeting the coarse-grained fraction of previously deposited tailings. The operation of the tailings disposal process was designed to result in the segregation of the coarse fraction from the fine-grained fraction using hydraulic settling. The sluiced tailings were discharged from the top of the dam crest onto the upstream side of the berm, with the intent of the coarse tailings fraction settling near the berm and the fine-grained fraction flowing with the sluice water to a lower elevation some distance from the berm.

The Starter Dam included features that impeded drainage through the toe. No significant internal drainage was installed during the construction of later dam raises, aside from small drainage blankets and chimney drains in some of the upper raisings. Seepage from the dam face above the toe was observed periodically from as early as the Fourth Raising. Despite the end of tailings deposition in mid-2016, review of piezometers installed within the dam showed the water level within the dam did not reduce significantly after tailings deposition ceased.

Between October 2018 and the date of the failure, nine boreholes were drilled in the central and upper region of the dam to install inclinometers and piezometers. The dam showed no signs of distress during this drilling, and no deformations related to drilling were detected. At the time of the failure, people were working on the dam and a drilling rig was being used to install piezometers.

Failure

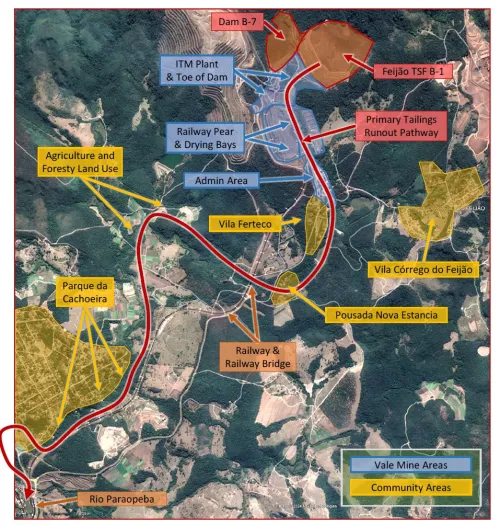

At 12:28pm on January 25, 2019, Dam B-1 failed catastrophically, killing 272 people and causing extreme environmental damage in the Paraopeba River watershed. When the dam failed, 9.7 million m3 of liquefied mining waste - 75% of what was stored - was suddenly released downstream, engulfing the mine’s railway, administration and maintenance area, including a canteen where miners were having lunch. The tailings progressed rapidly downstream destroying homes, farms, and roads. The mud covered an area equivalent to 450 football fields. The slurry traveled downstream to the town of Brumadinho, reaching speeds up to 120 km/hr, as it destroyed buildings and buried people caught in the runout zone. After flowing for more than 5 miles downstream, the mudflow reached Paraopeba River, causing significant harm to wildlife in its path.

The failure was captured on video, showing a slope failure that developed across 80% of the face of the dam in about 5 seconds. Collapse of the dam was complete in less than 10 seconds. The initial failure was followed by a series of retrogressive slope failures that progressed upwards through the tailings.

272 people were killed, including two people who were pregnant. 258 of the 272 deaths were workers. The failure resulted in the biggest accident at work in Brazil, causing dozens of injuries, in addition to the death of hundreds of workers from the company and its subcontractors. Three locomotives and 132 wagons were buried. The mud destroyed two sections of a railway bridge and about 100 meters of railway track. It buried buildings to their rooftops and an extensive field of mud cut off roads. The tailings plume reached the Paraopeba River and impacted the water supply for indigenous and quilombola communities and for several cities, including Brumadinho, Pará de Minas and Belo Horizonte.

There was an alarm system in place to warn the population at risk in the runout zone if Dam B-1 burst, but the failure process progressed too quickly for workers to identify and confirm the failure and to activate the alarm system. Vale told The Associated Press that the area had eight sirens, but “the speed in which the event happened made sounding an alarm impossible” when the dam burst. The dam was extensively monitored using survey monuments along the crest of the dam, inclinometers, and piezometers. None of these methods detected any significant deformations prior to failure.

Following the disaster, firefighters from the State of Minas Gerais led rescue efforts and were aided by international teams. The pace of rescue efforts was hampered by treacherous mud, making it difficult for rescuers to walk and requiring them to crawl at times. The sea of reddish-brown mud that surged out when the dam breached was up to 24 feet (8 meters) deep in some places, and to avoid the danger of sinking and drowning, searchers had to carefully walk around the edges, slowly crawl out onto the muck, or be transported into key areas via helicopter.

Courts froze about $3 billion of Vale assets for state emergency services and criminal charges were filed against Vale. On January 29, 2019, Brazilian authorities issued arrest warrants for five employees of the mine. Two senior managers of the mine and another Vale employee were arrested, along with two engineers who had been contracted to inspect the dam.

Causes & Consequences

Investigations concluded that the failure was the result of flow (static) liquefaction within the tailings in the dam. The videos show that the initial failure was relatively shallow and was followed by a series of rapid shallow slips with steep back slopes that progressed backwards into the tailings impoundment. The material in the dam showed a sudden and significant loss of strength and rapidly became a heavy Newtonian fluid that flowed downstream at a high speed.

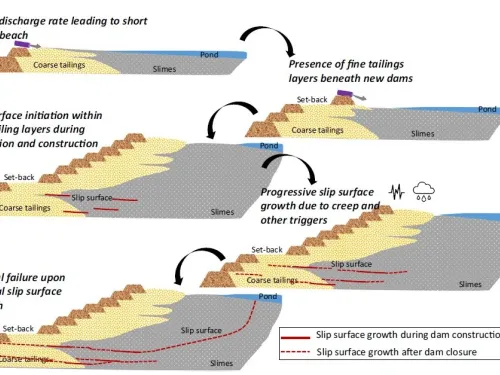

Pre-failure aerial and satellite images show that, at times during the life of the dam, water was close to the crest of the dam, resulting in saturation of weak tailings close to the crest and interbedded layers of fine and coarse tailings within the dam. A setback in construction of the dam also moved the upper portion of the dam over weaker, fine-grained tailings.

Geotechnical investigations conducted between 2005 and 2019 provided a detailed profile of subsurface conditions and confirmed that the materials under the dam were composed of interlayered coarse and fine tailings. Laboratory testing showed that the tailings were mostly loose, saturated, and had a high iron content, which resulted in heavy, stiff tailings that were potentially very brittle if triggered to become undrained. The amount of strain required to trigger strength loss could be very small, especially in the weaker fine tailings. Tests also found that loose tailings would slowly deform over time under a constant load, a process known as creep.

Some uncertainty remains as to what triggered the sudden loss of strength and subsequent liquefaction. The sudden failure was not triggered by an earthquake or blasting. There were no earthquakes recorded in the region on the day of the failure, and although blasting occurred in the open pit mines nearby, there was no blasting recorded on the day of the failure. An expert panel1 hired by Vale to assess the technical causes of failure identified several factors that contributed to the failure:

- Designs that resulted in an overly steep upstream slope constructed over weaker fine tailings;

- A lack of internal drainage that created a high water level in the dam;

- Water management that allowed ponded water close to the crest of the dam;

- Seasonal high rainfall that produced a small loss of strength in unsaturated materials above the water level; and

- High iron content in the tailings resulted in heavy tailings with bonding between particles.

These conditions resulted in a marginally stable dam that was close to failure in undrained conditions. The expert panel1 concluded that the failure of Dam B-I was due to a critical combination of ongoing internal strains due to creep, and a strength reduction due to loss of suction in the unsaturated zone caused by the intense rainfall towards the end of 2018. Another expert panel2 appointed by the Federal Public Prosecutor’s Office concluded in 2021 that the tailings were not bonded, and that the drilling of a borehole was a potential trigger of liquefaction.

A recent study by Zhu et al3 in 2024 suggests that the trigger was delayed slip surface growth along weak layers, likely influenced by creep deformation. The fine tailings layers provided a point of initiation for slip surfaces to form and propagate progressively under the increasing weight of the dam during its construction and raisings. The length of the slip surface within the weaker fine layers was not enough to cause failure of the dam during and immediately after its construction. While the weight of the dam stopped increasing after the dam closure in 2016, the slip surfaces continued growing within the fine tailings layers under the constant external loads, driven by the creep deformations. This growth was very slow and unstable, and the slow process continued, until the length of the slip surface reached the critical value, triggering the classical catastrophic slip surface propagation and subsequent dam failure.

Vale entered into an agreement with the State Attorney General’s Office of Minas Gerais, the Public Prosecutors’ Office of Minas Gerais, the State Public Defenders’ Office of Minas Gerais, the Federal Attorney General’s Office, the Federal Public Prosecutors’ Office, and the Federal Public Defenders’ Office, and committed to make monthly emergency aid payments to affected individuals through October 2021. Vale is also subject to a legal requirement to eliminate upstream-raised tailings storage facilities; their goal is to phase out 100% of upstream-raised dams by 2035. The company also enhanced dam risk management by adopting international standards post-incident, including a Global Industry Standard on Tailings Management (GISTM).

References

(1) Robertson, P.K., de Melo, L., Williams, D.J. & Wilson, G.W. (2019). Report of the Expert Panel on the Technical Causes of the Failure of Feijão Dam I.

(2) Arroyo, M. & Gens, A. (2021). Computational Analyses of Dam I Failure at the Corrego de Feijao Mine in Brumadinho. Final Report for VALE S.A., August 2021.

(5)Johnstone, W., & Morrill-Winter, J. (2024). Application of USACE LifeSim to the Feijão Dam B-1 Tailings Storage Facility Failure of January 25, 2019. Proceedings of Tailings and Mine Waste 2024. Civil and Environmental Engineering, Colorado State University.

(7) Vale dam disaster: $7bn compensation for disaster victims. (2021, February 4). BBC.

This case study summary was peer-reviewed by William Johnstone, Ph.D., P.E. (Spatial Vision Consulting Ltd.) and John W. France, P.E. (JWF Consulting LLC).

Lessons Learned

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn more

Static liquefaction should be considered as a potential failure mode for dams that have loose sands or silts in their embankments or foundations.

Learn more

Timely warning and rapid public response are critical to saving lives during a dam emergency.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- Tailings dams constructed using the “upstream method” have been found to be more susceptible to liquefaction, especially when the tailings behind the dam are saturated.

- Tailings dams are always under construction until their closure. This requires on-going evaluation to adapt and respond to changing conditions.

Global Industry Standard on Tailings Management

Safety Guidelines and Good Practices for Tailings Management Facilities

Safety Topic: Impoundments and Dams

Planning, Design, and Analysis of Tailings Dams

Dam Safety Toolbox - Tailings