Harmony Gold Mine No. 4 Tailings Dam (South Africa, 1994)

Background on Tailings Dams

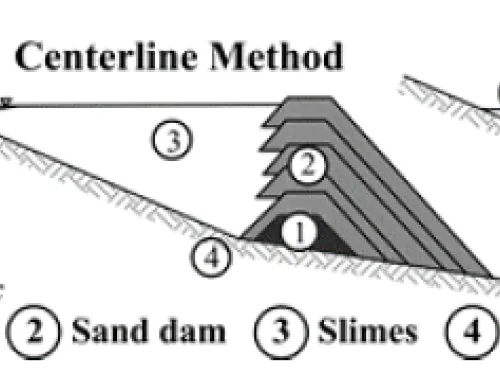

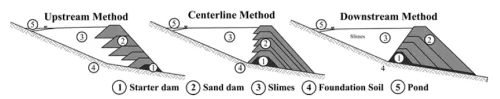

Mine tailings, also referred to as “slimes,” are the waste result of mining and processing minerals. The tailings are typically a mixture of sand, silt, metals, chemicals, and water; they can be solid, liquid, or a slurry of fine particles, and are often toxic and potentially radioactive. Tailings are usually discharged as a slurry to a tailings storage facility such as a tailings dam. Tailings dams are typically constructed with a starter dike sized to impound the initial two or three years of tailings plus accommodation for storm storage. Over time, the dike is raised with the rising elevation of tailings. Tailings dams are generally constructed using one of three methods: upstream, downstream, and centerline, which refers to the direction the crest moves in relation to the initial starter dike as the dam is raised. In the upstream method, a starter dike is constructed, then tailings are discharged around its crest to form a beach. The beach then becomes the foundation for a second perimeter dike, and the process continues. In the downstream method, tailings are initially discharged behind a starter dike. The dike embankment is raised by placing fill on the downstream side of the embankment. In the centerline method, a starter dike is constructed, and tailings are discharged from the dike crest to form a beach. The embankment is raised by placing fill on the beach and the downstream slope of the embankment simultaneously. The upstream method is generally the least costly but provides the least stability. Conversely, the downstream method generally provides the most stability but is the costliest.

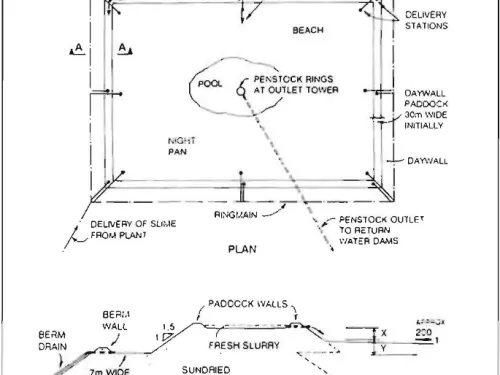

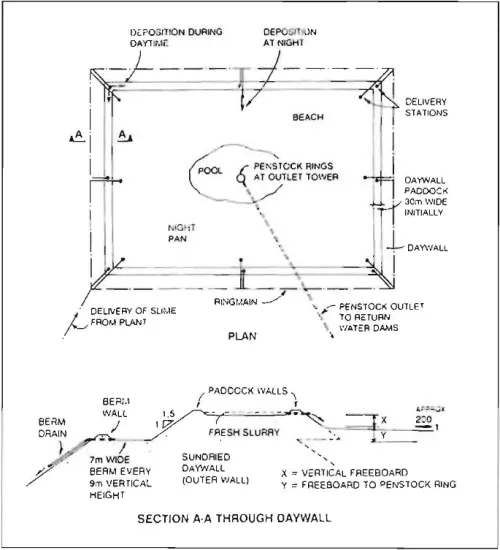

South African gold tailings impoundments are typically designed and operated as perimeter ring dikes with the tailings embankment raised using a variant of the upstream method with a “daywall-nightpan paddock” system. The outer perimeter of the tailings dam is referred to as the “daywall.” The daywall is raised to provide freeboard and to allow for maximum time for evaporation and desiccation, which is usually around three weeks on average. As a level of the daywall paddock embankment becomes sufficiently dry, the next level of paddock wall is built up in order to receive the next batch of tailings. The rate of rise is typically 1 to 3 meters (3 to 10 feet) per year. These operations are conducted under supervision during the day, hence the name daywall. Discharge of tailings can also occur overnight without supervision; into an area often referred to as the “nightpan.” Tailings discharged into the nightpan make their way towards a penstock outlet tower, which is normally located in the center of the nightpan area of the dam and is used to decant, or gradually drain water, without disturbing the tailings sediment.

Control of the phreatic surface is the single most important factor in maintaining the stability and the serviceability of tailings dams. Deposition of tailings occurs by open-ended pipe discharge, or in some cases, by spigotting or cycloning (separation of tailings into finer and coarser fractions using centrifugal force). Impoundments can be operated as one or more isolated compartments, each with its own delivery and decant system.

History of the Harmony Gold Mine No. 4 Dam

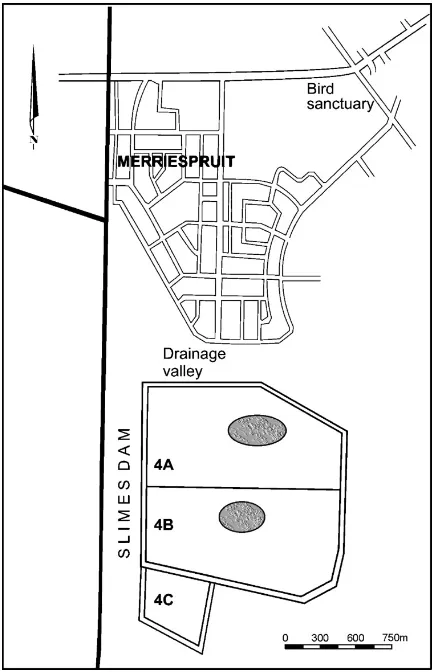

Merriespruit is a community in the township of Virginia in the Free State Goldfields of South Africa. It is located in the Witwatersrand Sedimentary Basin which contains the world’s largest accumulation of gold. In South Africa, the mining sector is the single largest generator and accumulator of solid waste. The township of Virginia was developed in 1936 with the discovery of the Free State Goldfields. The 250-home community of Merriespruit was built near the Harmony Gold Mine in 1956 to provide housing for mine personnel. When the construction of the Harmony Gold Mine No. 4 Tailings Dam began in 1978, just 300 m (1,000 feet) away from Merriespruit, the community already existed for over two decades.

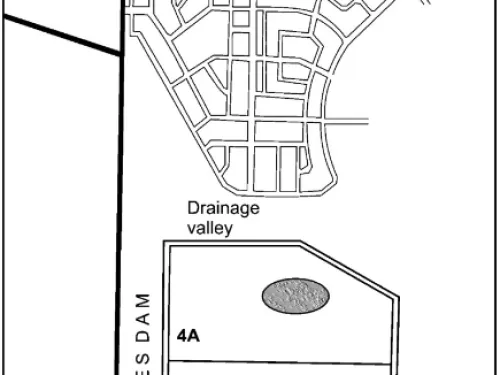

The construction of Harmony Gold Mine No. 4 Tailings Dam was initiated in 1978 using the upstream semi-dry paddock method. The dam was designed by the mine's metallurgical manager and a representative of the tailings dam contractor. At the time, tailings dam design in South Africa was performed largely by rule of thumb. A geotechnical investigation was not performed. The dam consisted of three compartments: a northern compartment (4A), a southern compartment (4B), and a small emergency compartment further to the south (4C). A single ring dike, also referred to as a perimeter dike, around the dam was not provided, nor did it have a return water dam to decant, or drain, water off of the dam; instead, the penstock decanted into a sump, with gravity flow back to the plant. Three pipelines delivered tailings to the compartments. The No. 1 delivery pipe was a problem throughout the life of the dam because of high friction head, frequent choking, and pipe bursts. As a result, the pool was difficult to control early on in the dam’s life; the pool was frequently located off the penstock, which likely affected drainage and decanting.

While not many details regarding the day-to-day activities of the construction and management process of the dam are known, the timeline of events leading up to the failure provides a compelling story of warnings gone unnoticed or unheeded. In 1985, consulting engineers were hired by the owner to assess the condition of the dam; at the time, the maximum height was 17 m (56 feet) at the location of the future breach. Eight piezometers were installed and three CPTs were performed, along with test pits in foundation soils, and lab testing for gradation, Atterberg Limits, and shear strength. Results indicated that the site had a silty sand layer that extended about 1.5 m (5 feet) in depth, underlain by a clayey sand/silty clay alluvium over weathered mudstone, siltstone, or sandstone. At the location of the critical section (and the future failure location), a drainage depression was encountered and considerable seepage was observed in the test pit. In this section, a loose clayey sand and very soft sandy clay extended to a depth of 1.5 m (5 feet), overlaying sandstone. A stability analysis was performed; the factor of safety estimated for the 17 m (56 foot) high dam was 1.4, and using a projected dam height of 35 m (115 feet), the factor of safety decreased to 1.2. The assessment concluded that the dam was in good condition with no toe seepage or sloughing observed and no stability concerns were noted.

The following year, in 1986, a Government Notice exempted the Harmony Gold Mines from the provisions of the regulation of the Water Act No. 54 of 1956 (as Amended by Act No. 96 of 1984) for 5 years until 1991, which would have classified the dam as a “Category III” based on size and hazard potential, which would have required the “maximum safety precautions”. It is not apparent to the authors of this paper as to why the mine was exempted multiple times from the Government Notice. Perhaps if the exemption had not been made, the dam may not have failed.

It is not clear when sloughing on the northern wall (at the location of the future breach) was first observed; however, by 1991, the sloughing on the northern wall increased, resulting in a small dumped rock buttress being placed against the face of the slope; this proved to be unsuccessful in preventing sloughing. Also in 1991, the Minerals Act was passed in South Africa, requiring tailings dams to have sufficient capacity to contain the 100-year 24 hour storm with 0.5 m (1.6 feet) of freeboard. However, Harmony Gold Mines’ exemption was extended for another 2 years until 1993.

In November 1992, it was decided to repair the seepage and sloughing on the northern wall of Compartment 4A by forming a hydraulically-placed buttress at the toe of the dam and depositing tailings into the area. The buttress was about 90 meters (295 feet) long and 9 meters wide (30 feet).

In 1993, there was a change in the ownership’s management structure in which four plants were brought under the supervision of a single manager. This caused a reduction in personnel working at the dam and also reduced the number of managers overseeing operations at mining facilities, which in turn resulted in fewer hours spent on overall operation and oversight of each of the mining facilities - most importantly, the tailings dams. This also resulted in less training for operational and managerial staff. At the Harmony Gold Mine, “the four reduction plants were brought under a single metallurgical manager who, up to that time, had not been responsible for the Merriespruit operations”. In this same year, seepage was noted on the northern wall above the drain exit, and a patch was constructed with cladding. After discussions with the operator, it was agreed in March 1993 that all deposition in Compartment 4A should be stopped. However, whether the order to stop tailings deposition into Compartment 4A was not clearly communicated or was ignored, tailings continued to be deposited into Compartment 4A.

The Government Notice exemption was extended for another 2 years until 1995. In April 1993, the operator performed a slope stability analysis using assumed strength parameters and a circular slip failure model yielding a Factor of Safety of 1.34 for the northern wall, where the breach later occurred.

The division wall between Compartments 4A and 4B breached some time before the dam failure in 1994, though the exact date of the division wall breach is unknown. It resulted in drainage from Compartment 4B flowing into Compartment 4A, where it then collected in the pool of Compartment 4A. The pool, rather than making its way to the penstock, as intended, continued to collect against the northern wall of Compartment 4A. This additional drainage from Compartment 4B increased the size of the pool in 4A and reduced the freeboard at the northern wall to 300 mm (less than 12 inches). In addition, the pool on compartment 4A was progressively pushed away from the penstock/decant pipe towards the northern wall, a feature that developed months before the disaster. Compounding the problem, there were also reports of the drain outlets not working properly due to clogging from various causes such as fungal growth, chemical precipitation, and mud and slime buildup.

The low relative density of the material used in the construction of the embankments, particularly that of the north embankment, was identified as a major cause of what was described by investigators as an “inferior daywall” making up the northern embankment of Compartment 4A. In discussions with the operator’s head office supervisor, who had been in charge of the dam for many years, it revealed that the slurry received from the reduction works in the early years often had a low relative density. He reported difficult dam building conditions with seepage and sloughing on the northern wall.

Dam Failure and Consequences

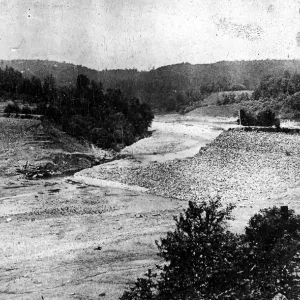

From October 1993 to early 1994, the summer in Free State was particularly wet. On Tuesday, February 22, 1994, a storm produced approximately 32 mm (1.26 inches) of total precipitation. According to Strydom and Williams [9], “The most intense precipitation was about 20 mm (0.79 inches) in a period of about 20 minutes after 18:00 and this would be an event with a five-year recurrence interval, which is nothing out of the ordinary”. Eyewitnesses reported seeing water flowing over the top of the crest of the northern wall of the dam in the evening of February 22 at about 7 p.m., two hours before the failure. At 9 p.m. that night, a sudden failure of the dam at the northern wall occurred, and a 450-foot wide breach formed, releasing about 630,000 m3 (500 acre-feet) of tailings slurry through Merriespruit. The flood wave was 2.5 m (8 feet) high when it hit the first homes in the town, knocking some of them off their foundations. Since the failure occurred at 9 p.m., some people were already in bed when the failure occurred and found themselves suddenly floating in their beds against the ceiling; others were blinded by the contaminated mud.

As a result of the failure, 17 people were killed, 80 properties were destroyed, and widespread damage to the environment occurred. More than 200 people were injured. The disaster caused $17 million (USD, 1994) in damages (approximately $35 million in 2023 dollars). First responders waded through the chest-high slurry of contaminated tailings that contained cyanide; they could feel the chemicals in the mud burning their skin as they searched and yet they continued their search and rescue efforts. Since the failure happened at night, it was dark and rescue operations were difficult and dangerous. Helicopters illuminated the scene from above while ambulances ferried survivors away to nearby hospitals. Blocks of homes were swept off their foundations.

Following the disaster, the Minister of Justice established a joint Inquest/Inquiry led by a judge. The court proceedings started on March 15, 1994 with the final judgment issued the following year in 1995. The Operator, the Owner, and the State were all represented in the investigation and court proceedings, along with an insurance company and the Mine Workers Union.

For the first time in South African history, satellite imagery was used in the forensic investigation of the failure and entered as scientific evidence in court. Through the use of satellite imagery, it was determined that there was a considerable amount of water on the dam over a long period of time before the failure. In the imagery, changing moisture conditions are indicated by changes in hue; the wetter the soil surface, the darker it appears in the infrared imagery. Using an image from February 1, 1994, three weeks before the failure, the pool elevation was estimated at only 0.45 m (1.5 feet) below the crest. Legislation required that the dam have capacity to contain the 24-hour, 100-year storm event with 0.5 m (1.6 feet) of freeboard; the dam did not meet this criterion. Afterwards, operating staff denied that the pool was not located around the penstock outlet in 4A and claimed that it was instead located against the northern wall, until confronted with satellite imagery. The imagery showed that the pool in compartment 4A was not located around the penstock outlet, but was instead ponded against the northern wall and had been for a considerable period of time. Coupled with eyewitness reports, the satellite imagery provided evidence of overtopping as being a critical contributing factor to the failure. The overtopping caused erosion of the slope, which is believed to have resulted in progressive slope failures, which then triggered a static liquefaction flow failure of the metastable tailings.

On April 1, 1995, a judge found six employees of Harmony Gold Mine and mining company Fraser Alexander, who managed the dam, criminally liable for the disaster; three employees of the mine were found guilty of culpable homicide but the homicide charges were later dropped. Instead, they were found guilty of contravening Section 37 of the Minerals Act. Harmony Gold Mine and Fraser Alexander were ordered to pay relatively small fines totaling R270,000 (less than $15,000 USD in 1994). For comparison, the mine’s profits in 1995 were about R56 million ($3 million USD in 1994).

The inquiries and investigations into the Harmony Gold Mine Tailings Dam No. 4 concluded: “It is not clear why the Mines were initially exempted, for a period of 5 years, from the regulations under section 9C on Safety of Dams (promulgated under the Water Act in 1986) and then for two additional periods of 2 years. There appears to have been sufficient legislation to have avoided this sort of disaster, if only it had been applied.”

Following the failure of the Harmony Gold Mine Tailings Dam No. 4, South Africa drafted a Mandatory Code of Practice on Mine Residue Deposits in 1995 for the design, operation, and closing of tailings dams and formally adopted it in 1998. The Code established new standards for design criteria, water management, qualifications for tailings dam management personnel, and proximity to population at risk; it also required every tailings dam to be classified by hazard potential, and regular auditing by experienced professional engineers.

The failure of this dam was fundamentally due to human factors. If the dam had been designed, built, maintained, and/or operated differently, as described below, the failure could have been prevented. And if the dam had not been sited right next to the town or if warning signs had been heeded, loss of life could have been prevented. There were several warning signs of instability at the northern wall which were not recognized as warning signs or were ignored. These included seepage and sloughing at the northern wall over a period of years, which continued despite repeated efforts to buttress the wall, and reduction of freeboard in Compartment 4A which was known to operations staff, but apparently not known to management. There were also indications that runoff had flowed into the town from the dam several times in years prior to the failure, and that may have also been due to overtopping, but this was not recognized as a warning sign that the northern wall could become unstable due to ponding of water adjacent to the wall and erosion of the slope due to overtopping.

In a broad context, during the period of operation of this dam, gold prices began to decline, which, coupled with rising production costs, placed financial strain on mining companies. The profitability of gold mining decreased, leading to closures of less profitable mines. As detailed below, these cost pressures were undoubtedly a fundamental contributing factor in the failure of this dam.

Human Fallibility and Limitations

Humans are inherently fallible and limited, and this is generally an underlying contributing factor for all dam failures. Human fallibility and limitations are associated with misperception, faulty memory, ambiguity and vagueness in use of language, incompleteness of information, lack of knowledge, lack of expertise, unreliability of intuition, inaccuracy of models, cognitive biases operating at the subconscious level and group level, use of heuristic shortcuts, emotions, and fatigue. In the particular case of this dam, human fallibility and limitations were evident in the form of human errors across many individuals:

- The people involved in siting the dam next to the town either didn’t recognize the risks of doing so, or were generally overconfident about their ability to manage the risks and design, build, and operate a safe dam. The parties involved may have also been technically inexperienced and not fully understanding the potential consequences of a major failure, should one occur. At the time in the tailings dam industry, there was an incorrect perception that gold mine tailings were not liquefiable, and this likely contributed to underestimating the risk of a flow failure which could inundate the town.

- There was an awareness among people involved in building the dam that the material being placed in the northern wall was loose (low relative density), but the implications of this looseness apparently were not recognized or understood.

- The geotechnical engineer who evaluated the stability of the northern wall evidently overestimated the factor of safety, with estimates ranging from 1.2 to 1.4. This may reflect a lack of expertise or incorrect assumptions.

- The people involved in repeated efforts to stabilize the northern wall evidently didn’t understand the physics of the slope well enough to stabilize it properly. They also didn’t know or understand that the embankment materials at the northern wall were susceptible to liquefaction.

- The operations personnel didn’t understand the significance of tailings-laden water continuing to be placed in Compartment 4A in violation of a stop work order, resulting in the freeboard being reduced, increasing potential for overtopping, and decreased stability of the northern wall.

- Prior to this dam failure, overtopping of tailings dams had not typically resulted in stability failures, so there was likely a lack of recognition in the tailings dam industry that overtopping could result in stability failure.

Risk Management Inadequacies

Human errors and the underlying drivers of failure noted above often lead to inadequate risk management. Inadequacies in risk management may be classified into three types:

- Ignorance involves being insufficiently aware of risks. This may be due to aspects of human fallibility and limitations such as lack of information, inaccurate information, lack of knowledge and expertise, and unreliable intuition. Complexity can also contribute to ignorance.

- Complacency involves being sufficiently aware of risks but being overly risk tolerant. This may be due to aspects of human fallibility and limitations such as fatigue, emotions, indifference, and optimism bias (“it won’t happen to me”). Pressure from non-safety goals, such as cost pressure, can also contribute to complacency.

- Overconfidence involves being sufficiently aware of risks, but overestimating ability to deal with them. This may be due to aspects of human fallibility and limitations such as inherent overconfidence bias, which results in overestimating knowledge, capabilities, and performance.

In the case of this dam, it appears that the people involved with the dam were generally ignorant of the risks, mostly because they lacked expertise. The fact that they made efforts to repair and buttress the north wall slope indicates that they were trying to address what they perceived to be risks, but they didn’t recognize the magnitude of the risks. Tailings continuing to be pumped into Compartment 4A after the stop work order may indicate that those operations personnel didn’t understand the importance of pool management, freeboard, and the risk of overtopping, especially since overtopping had occurred at other tailings dams without causing slope failure, and overtopping may have occurred several times at this dam in past years without causing failure.

With respect to complacency, it is possible that operations personnel who continued pumping tailings-laden water into Compartment 4A (or into 4B, knowing that the wall between 4B and 4A was breached) understood that they were taking a significant risk, and just accepted the risk, possibly due to cost pressure, pressure from upper management to get rid of the tailings-laden water, or even just laziness. And finally, with regard to overconfidence, siting this large tailings dam right next to the town suggests overconfidence in ability to manage risks.

Safety Culture

Counterbalancing the drivers of failure noted above, the human factors contributing to system capacity for safety generally emanate from what is routinely referred to as “safety culture.” The general idea of safety culture is that individuals at all levels of an organization place high value on safety, which leads to a humble and vigilant attitude with respect to preventing failure. For such a safety culture to be developed and maintained in an organization, the senior leadership of the organization must visibly give priority to safety, including allocating the resources and accepting the tradeoffs needed to achieve safety.

In the case of this dam failure, in hindsight, it appears that the safety culture of the South African gold mining industry, the Harmony Gold Mine, and the people involved with this particular tailings dam was lacking. Evidencing this, Wagener et al. note that, preceding this dam failure, “despite knowledge gained from, on average, two tailings dam failures every year in South Africa, the Merriespruit disaster still occurred”.

Best Practices

Experience in dam safety shows that strong safety cultures naturally lead to at least meeting standard practices, and sometimes also implementation of numerous best practices for dam safety risk management. As a corollary, dam incidents and failures are typically preceded by long-term cumulative neglect of numerous standard and best practices. This dam failure was not exception to this rule, because many standard and best practices were not followed:

- General Design and Construction Best Practices: It appears that some standard and best practices were not applied in the design, construction, and operation of this dam. In particular, the dam lacked a ring main and a return water secondary dam to capture runoff.

- Design Conservatism: Despite using the daywall paddock method of construction, it appears that the daywall materials in the north wall were too loose and therefore lacked shear strength. In addition, the history of erosion and sloughing at the northern wall suggests that the slope may have been too steep. The lack of freeboard was also a contributing factor to the failure, because it resulted in overtopping from a storm with 2 inches of total rainfall over the dam.

- Budget, Resources, and Resilience: Cost pressures were a fundamental contributing factor to this failure. The dam was understaffed with respect to management, engineering, and operations. Wagener (1997) notes that only one geotechnical engineer was involved in the dam, and his involvement was limited: “The contractor had a head office geotechnical engineer who attended some of the regular meetings at the mine. The geotechnical engineer was the only Professional Engineer involved, and only occasionally on request by the contractor’s local office. His role was vague and he was not kept fully informed by site staff. Comment: a superficial involvement and vague job definition can lead to dangerous situations.”

- Humility, Learning, and Expertise: If the dam was designed by the metallurgical manager, and that person was not a qualified engineer, that may indicate a lack of design expertise. The inability to properly evaluate and stabilize the northern wall suggests lack of expertise. In addition, personnel were promoted to positions for which they weren’t qualified, and didn’t receive adequate training, and that likely contributed to making bad decisions, such as continuing to pump tailings-laden water into Compartment 4A.

- Cognitive Diversity: Having only one geotechnical engineer involved in the project, and with limited involvement, indicates lack of cognitive diversity.

- Decision-Making Authority: It appears that operations personnel were able to decide to continue to pump tailings-laden water into Compartment 4A, in violation of the stop work order. If management were monitoring the operations at the dam, that pumping may not have happened.

- System Modeling: There was a lack of awareness of potential failure modes and consequences, including the failure mode that actually occurred. While efforts were made to stabilize the slope, it was apparently not realized that overtopping could lead to slope failure. It was also not realized that the tailings were susceptible to static liquefaction, which could result in a tailings flow into the town. There was also no emergency action plan, but there was sufficient time between when the dam overtopped and water flowed into the town, versus when the dam failed, so it would have been possible to evacuate the town quickly enough if the dam was being closely monitored.

- Information Management: There is evidence that there were poor communications, especially related to the stop work order and its implementation and enforcement. Wagener (1997) notes that: “The regular meetings at the mine between the contractor’s local staff and the mine were poorly documented and responsibilities for action were not always clearly defined. This led to many ‘grey areas’ and arguments at the enquiry, with each party accusing the other of lying. Comment: It is essential that proper minutes be kept of all meetings, clearly spelling out decisions made and action required from all parties.” Wagener (1997) also notes that: “The contractor’s geotechnical engineer was severely reprimanded by the court for not going to the top of the dam and noting the low freeboard during a visit to the unstable wall a few months before the disaster. However, he was not informed by his own local staff that the dam was receiving slime. Comment: it is necessary that proper and meticulous inspections be done. However, the geotechnical engineer cannot be expected to do the work of a detective, and has to be kept fully informed by the field staff.”

- Warning Signs: Warning signs were recognized, but the magnitude of the risk was not recognized. It was observed that the northern wall was having seepage and sloughing issues, remedial actions were attempted, and stop work was ordered for Compartment 4A, which suggests that risk of slope failure was recognized, despite calculated factors of safety of 1.2 or more. However, it was apparently not recognized that the actual factor of safety of the slope was closer to 1.0, that ponded water against the crest of the northern wall had reduced freeboard, that a moderate storm could result in overtopping of the north wall, that the overtopping erosion could trigger slope failure, and that failure of the northern wall could lead to static liquefaction flow failure of the contained tailings.

- Standards: For unknown reasons, the dam had received multiple exemptions with respect to regulatory requirements, and therefore it can be argued that the standard of care was not met. If those exemptions had not been granted, it is possible, perhaps likely, that a different course of action would have been taken, with the result that the dam would not have failed.

The failure of the Harmony Gold Mine No. 4 tailings dam can ultimately be attributed to human factors, specifically a series of poorly-judged managerial and operational decisions which spanned years prior to the failure and stemmed from a poor economic climate and cost-cutting pressures. The operators of the dam lacked the technical expertise to adequately address documented and observed problems in the design, construction, and the operation of the facility, and a proper assessment of the situation was not sought out or requested from an unbiased third party. Additionally, the operators of the facility demonstrated a lack of understanding of the risks and consequences associated with a potential failure either due to a lack of technical expertise or overconfidence in their ability to address the documented problems at the facility. Furthermore, a breakdown of communication led to the continuation of the deposition of tailings on the structure when conditions were observed to be unsafe. This all created a situation in which an ordinary storm for the area triggered the failure of the structure, over $17 million (USD, 1994) in damages, and the death of 17 innocent individuals ranging in age from 2 to 71, all of which could have been prevented if only the warning signs had been recognized and heeded.

References

(4) Wagener, F. (1997). The Merriespruit Slimes Dam Failure: Overview and Lessons Learnt. Journal of the South African Institution of Civil Engineering, 39(3). South African Institution Of Civil Engineering.

(5) Williams, D.J. (2021) Lessons from Tailings Dam Failures—Where to Go from Here?. Minerals 2021, 11(853), 853. Geotechnical Engineering Center, School of Civil Engineering, The University of Queensland.

(6) Van Niekerk, H.J. & Viljoen, M.J. (2005). Causes and Consequences of the Merriespruit and Other Tailings Dam Failures. Land Degradation and Mitigation, 16(2), 201–212.

(8) Wagener, F.V.M., Craig, H.J, Blight, G., & McPhail, G. (1998). The Merriespruit Tailings Dam Failure - a Review. Tailings and Mine Waste ‘98 Proceedings, 925-952.

(9) Strydom, J.H. & Williams, A.A.B. (1999). A Review of Important and Interesting Technical Findings regarding the Tailings Dam Failure at Merriespruit. Journal of the South African Institution of Civil Engineering, 41(4), 1-9. South African Institution Of Civil Engineering.

(10) Gold FM 104.3 Welkom. (2021, February 22). Today we remember the Merriespruit disaster [Status Update]. Facebook.

(12) Minerals Council South Africa. (n.d.). We Care and We Remember: Merriespruit, 22 February, 1994.

(13) Pretoria FM. (2021, February 22). [Photo]. Facebook.

(14) Blight, G. & Fourie, A. (2014). A Review of Catastrophic Flow Failures of Deposits of Mine Waste and Municipal Refuse. University of the Witwatersrand, Johannesburg, South Africa.

(15) Staff Reporter. (1996, March 22). White-Collar Killers Walk Free. Mail & Guardian.

(16) Martin Creamer’s Mining Weekly. (1997). Martin Creamer’s Mining Weekly, 14(23), 13.

(19) Alvi, I.A. & Alvi, I.S. (2023). Why dams fail: a systems perspective and case study. Civil Engineering and Environmental Systems, 40(3), 150-175.

This case study was peer reviewed by Dino Bernardi, P.E. (Division of Safety of Dams, California Department of Water Resources).

Lessons Learned

Dam incidents and failures can fundamentally be attributed to human factors.

Learn more

Intervention can stop or minimize consequences of a dam failure. Warning signs should not be ignored.

Learn more

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn more

Static liquefaction should be considered as a potential failure mode for dams that have loose sands or silts in their embankments or foundations.

Learn more

Timely warning and rapid public response are critical to saving lives during a dam emergency.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- Tailings dams constructed using the “upstream method” have been found to be more susceptible to liquefaction, especially when the tailings behind the dam are saturated.

- Tailings dams are always under construction until their closure. This requires on-going evaluation to adapt and respond to changing conditions.