Meadow Pond Dam (New Hampshire, 1996)

Lynda Sinclair died on March 13, 1996, at the age of 48. She drowned trying to escape the flood torrent caused by the failure of Meadow Pond Dam in her town of Alton, New Hampshire (see Fig. 1 for location). However, the series of circumstances that led to her death started with the human failures of her upstream neighbor and those he hired to build the dam.

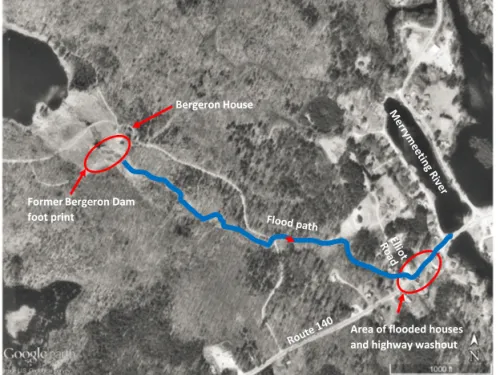

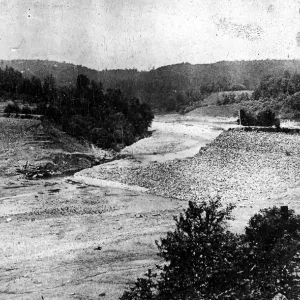

Bob Bergeron had the Meadow Pond Dam built in 1995 to create his own recreational lake. The 30-ft-high dam impounded a 44-acre pond containing 200 acre-feet of water, all of which was entirely on Bergeron’s property. Bob and his wife Virginia lived in their large house, referred to as the “Castle” by Alton residents, which was set on the lake and located about 0.6 miles above their nearest neighbors, who were on or near state Route 140 (see Fig. 2 for downstream aerial). Bob, who had never owned a dam before, much less constructed one, contracted the design and managed the construction. He selected Connie’s Septic Service, Inc. as the construction contractor and Putman Concrete for the concrete work.

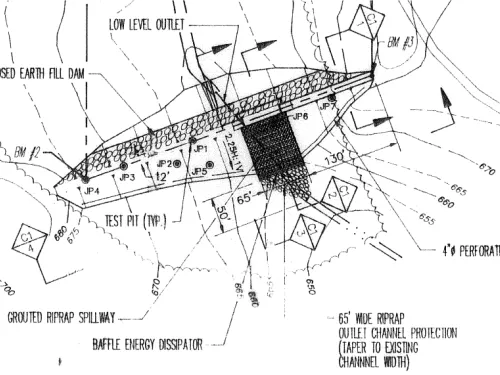

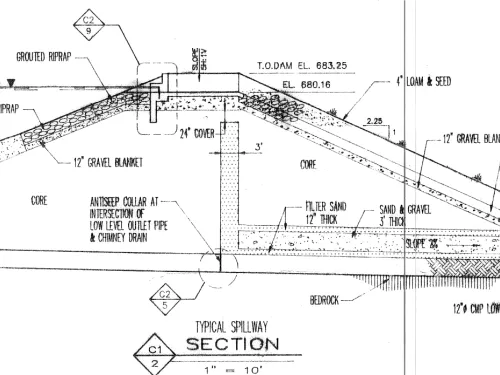

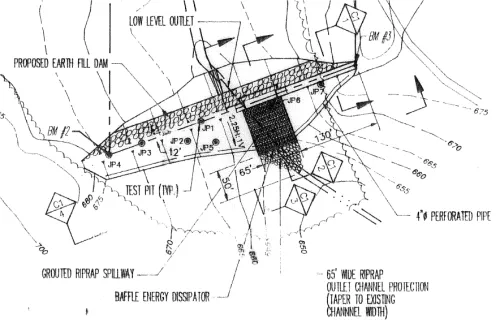

The embankment dam largely consisted of silty sand and gravel glacial till with a vertical filter sand chimney drain located just downstream of the centerline (see Figs. 3 and 4 for plan and section). The chimney drain connected to a filter sand and gravel blanket drain across the downstream half of the embankment. Riprap over a gravel blanket protected the upper 10 ft of the upstream slope.

The feature of most importance to the failure was the 65-ft-long (~weir length) reinforced-concrete slab spillway crest located across the left or east part of the embankment (see Fig. 4 for spillway section). The spillway crest was designed to have an unjointed 1-foot-thick reinforced-concrete seepage cutoff wall to a depth of 5 feet across the upstream side of the crest and abutment, and the spillway crest slab was to be set on a 2.25-ft-thick layer of clean gravel.

This construction team’s work deviated from the design in numerous aspects, some of which proved fatal. The cutoff wall was unreinforced, shorter, and more limited in length than designed and included an unspecified joint with no waterstop. The gravel blanket under the spillway slab ranged in thickness from 0 ft to 2.9 ft thick and contained layers of embankment till contamination and a higher-than-specified fines component. The spillway lacked a 5-foot-wide upstream bench, and zones of the embankment material were not compacted to the required density. Numerous other construction deviations from the specifications existed.

Virginia left their house in the early evening of March 13th, about 6:35 p.m. to attend a town meeting when she saw that the water level had risen to the bridge deck where their driveway crossed the stream from their pond about 0.4 mile below the dam. She returned home immediately and told her husband. Bob checked the dam, and, after seeing a 3-ft-diameter plume of water flowing from the face of the grouted riprap spillway channel, called 911 and told the dispatcher that his dam was failing. The Bergerons watched as their dam progressively deteriorated and an upstream vortex grew from a small whirlpool to a horseshoe-shaped waterfall to a 90-ft-wide breach the full height of the dam.

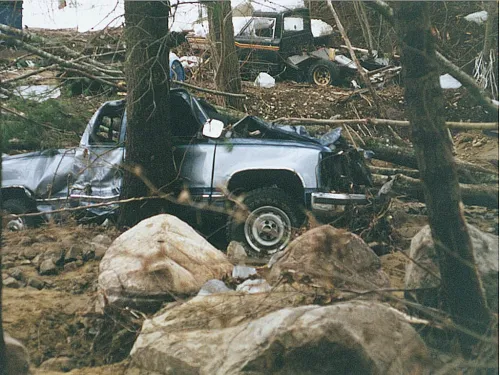

Downstream residents Lynda and Larry Sinclair had planned to renew their wedding vows that night, but those plans changed when Lynda saw the flood waters rushing downhill in front of their house. Taking the advice of the 911 dispatcher to flee, she and Larry left in separate vehicles – he in his semi-tractor with trailer attached and she in the family pickup. Neither vehicle was a match for the flood, which by now had eroded a large gully in Route 140. Larry’s semi jackknifed and submerged into the gully (Fig. 5). He was able to climb out of the cab onto the truck roof, where he was rescued with a rope. The flood waters grabbed, spun, and carried away Lynda Sinclair’s pickup. The crushed pickup was found after the flood in a downstream ravine (Fig. 6). Searchers discovered Lynda’s body six days later in the debris, which filled the Merrymaking River (Fig. 7). The Sinclair house was undamaged by the flood.

Investigators concluded that Meadow Pond Dam failed due to erosion and piping beneath the spillway slab. Investigators reported the following contributing factors:

- Shortened seepage paths around the end of the cutoff wall resulting from the shorter lateral extent (16 ft versus 27 ft) of the cutoff walls.

- Shortened seepage paths through the cutoff and slab through cracks resulting from a lack of longitudinal steel, settlement of the embankment, and ice lens heaving.

- Shortened seepage paths through the horizontal joint between the spillway slab and the cutoff wall, which was not included in the design and did not include a waterstop.

- Ice heaving of the slab due to contamination of the gravel layer and the lack of sufficient cover for frost-susceptible embankment material.

- Shortened seepage paths between the reservoir and the bottom of the cutoff wall due to lack of a 5-ft-wide level bench and due to poor design.

- Lack of adequate drainage in the spillway gravel layer due to high fines content, contamination, and irregular thickness.

Seepage and erosion induced the failure of Meadow Pond Dam, but the subsequent tragedy occurred because of human failings. The short story is that the owner did not issue the approved and permitted plans and specifications to the contractor building the dam, hired an inexperienced contractor and field engineer, and made or allowed changes to the original design to save money. Also, some dam design features were not consistent with best practices. In response to this tragedy, the State of New Hampshire made several changes to its dam safety statutes, regulations, and practices.

References:

(1) Castro, G. & Ward, C. (1996). Failure of Meadow Pond Dam. Proceedings of the Dam Inspection, Analysis, and Rehabilitation Seminar. American Society of Civil Engineers, Boston Society of Civil Engineers Section .

(3) Marr, W.A. (1996). Investigation into Cause of Failure of Meadow Pond Dam, Alton, New Hampshire. GeoTesting Express report prepared for State Farm Insurance Co.

(4) Trebilcock, B. (1996). The Night the Dam Broke. Yankee Magazine.

(5) Various Files from the State of New Hampshire, Department of Environmental Service, Dam Bureau.

This case study was peer-reviewed by James Gallagher, P.E., Retired NH Dam Bureau.

Lessons Learned

Dam incidents and failures can fundamentally be attributed to human factors.

Learn more

Emergency Action Plans can save lives and must be updated, understood, and practiced regularly to be effective.

Learn more

Timely warning and rapid public response are critical to saving lives during a dam emergency.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- Require monitoring of critical aspects of dam construction by a qualified construction engineer, who has the required years of experience in construction of similar dams and has been approved by regulators to serve as construction engineer.

- Require certification by the construction engineer of the date of the plans, specifications, supporting assumptions, and calculations; and that the construction engineer has reviewed them and understands the design and the intent of the design.

- Require notice from the owner and construction engineer to regulators at the start of construction, during or at significant construction milestones, and at substantial completion.

- Explicitly determine and state which aspects of construction must be observed full time by a representative of the construction engineer.

- Require documentation by the construction engineer of critical construction elements, deviations from the design, and construction operations and features that were and were not observed.

- Require an Emergency Action Plan (EAP) as part of any permit of a high or significant hazard dam. In addition, require an EAP for construction conditions where a high or significant hazard could result.

- Pay attention to all possible seepage paths in design, especially at structure-embankment interfaces.

- Provide filtered seepage collection systems consistent with current state-of-the-practice guidance for filter materials, geometry, and drainage capacity.

- Consider and protect against frost heave in the final as-built condition and during construction. Near structures that could be heaved, provide good drainage and either use non-frost susceptible materials or insulate to prevent heaving.

- Advise EAP-evacuated populations to move to high ground along routes that are out of the water and that travel through water must be avoided, especially if they are in a vehicle.

Forensic Investigation Meadow Pond Dam Alton, New Hampshire

The Meadow Pond Dam Tragedy: Human and Physical Failures