Barahona No. 1 Dam (Chile, 1928)

In 1917, up a steep canyon in the Andes Mountain range, construction of an earthfill dam, Barahona No. 1, was initiated to store tailings from the El Teniente copper mine near Santiago, Chile. Copper mine tailings are a slurry of ground rock, water, and chemical reagents used in the metallurgic process. The original design of the El Teniente tailings storage dam, known as Barahona No. 1, called for a 78-meter (~256 feet) high earthfill dam to be constructed from imported clay borrow material, raised progressively to accommodate deposition of tailings from the mine. Foundation preparation started in 1917, and soon after, earth materials were transported to the dam site using trains, then material was transferred to horse carts for distribution and compacted using steam rollers. Two years into construction the project was halted due to high costs and construction difficulties. The dam was 7 meters (~23 feet) high at the time construction stopped.

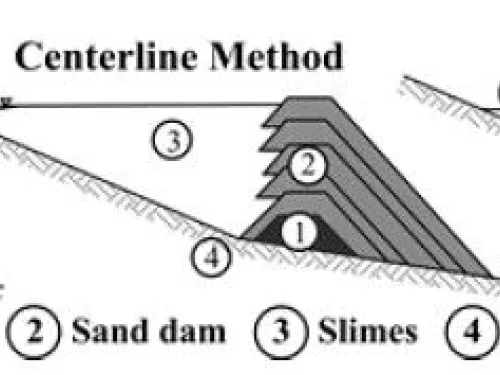

Tailings dams are constructed using one of three methods: upstream, downstream, or centerline, which refers to the direction the crest moves in relation to the initial starter dike as the dam is raised. In the upstream method, a starter dike is constructed and then tailings are discharged from its crest to form a beach upstream of the starter dike. The beach then becomes the foundation for a second perimeter dike. In the downstream method, tailings are initially discharged behind a starter dike. The embankment is raised by placing fill on the downstream side of the embankment. In the centerline method, a starter dike is constructed, and tailings are discharged from the dike crest to form a beach. The embankment is raised by placing fill onto the beach and the downstream slope of the embankment simultaneously. As a result of the construction difficulties of the tailings dam at the El Teniente mine, design changes were made, and a new starter dam was constructed downstream of the original. Deposition of the tailings in the reservoir started in March 1920. Construction of the new dam continued using the upstream method.

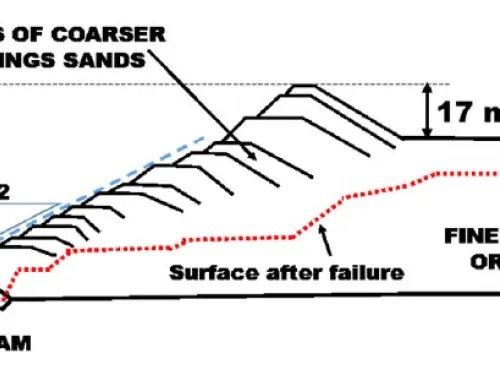

When the Talca earthquake (8.2-8.4M) struck central Chile on December 1, 1928, Barahona Dam No. 1 was 65 meters (~213 feet) high and 1,885-meters (6,184 feet) long with a 2H:1V downstream slope and stored 27 million tons of tailings waste. The dam, which was located just over 100 miles from the epicenter, survived the quake and then failed catastrophically moments later. A construction engineer witnessed the failure from his house about 1,000 feet away. He noted the dam failed two or three minutes after the end of the shaking, which lasted for about one minute 40 seconds. The cause of the failure was seismically induced flow liquefaction, resulting from a decrease in the shear strength of the tailings and large displacements of the sand embankments. The cyclic accelerations of the earthquake caused the deposited tailings to liquefy and the upper dikes near the left abutment settled. As a result, a 400-meter (1,312 feet) section of the dam failed near the maximum section of the dam. Four million tons of mine tailings were catastrophically released downstream into the steep canyon below, with wave heights reportedly over 60 meters (197 feet). 54 people were killed, and several bridges, a railroad, and agricultural crops were destroyed. This was the first recorded occurrence of an earthquake-induced collapse of a tailings dam in Chile.

The failed section of dam was repaired, and the dam was filled to a final elevation 17 meters (56 feet) below the original crest. A new tailings storage dam, Barahona No. 2, was initiated upstream of Barahona No. 1 in 1929 and was constructed using the downstream method. It remained in operation until 1936. Both dams performed satisfactorily during subsequent earthquakes of similar magnitude in 1985, 2010, and 2015.

In 1991, J.H. Tronsco, Professor of Geotechnical Engineering at The Catholic University of Chile, conducted a field investigation at the site of the Barahona No. 1 failure and performed piezocone penetration and standard penetration testing. He found construction by the upstream method resulted in interbedding of tailings and sands, with fines content of the tailings sands around 20%, while the fines content of the tailings stored in the pond was in the range of 83–92%. Tronsco determined that soils in the dam were not consolidated at the time of the earthquake. Increasingly large pore water pressures were generated by the cyclic seismic loading, which led to strains high enough to reach a critical steady state condition of minimum shear strength. Liquefaction of the tailings occurred in the impoundment and increased the shear stresses in the retaining dikes. As driving stresses increased while shear strength decreased to minimum residual values, factors of safety were reduced to less than one, large displacements occurred, and the dam failed. The design decision to switch from a dam built with clay borrow material to a dam built using the upstream method to deposit the tailings contributed to the failure because a portion of the dam was then founded on soft silts, which generated the high pore pressures during the undrained loading condition.

Notably, the Barahona dam failure occurred when soil mechanics as a field of science was in early stages of development (Karl Terzaghi’s The Mechanics of Earth Construction Based on Soil Physics was published in 1924; Arthur Casagrande postulated the concept of critical void ratio in 1935). The original drawings and engineering reports for the dam demonstrate an understanding of basic soil mechanics concepts, including the importance of classification and segregation of materials, and compaction. While construction of the dam using the upstream method was a high-risk undertaking, given the proximity of the population downstream, it was not an uncommon practice to construct tailings dams this way, and the practice continues today, though less frequently. The upstream method of construction is considered the least stable and highest risk because there is higher potential for foundation instability, since the walls of upstream tailings dams are raised over a base of unconsolidated mine waste slurry; excess pore water pressures can be generated as the dam is raised, increasing the load on the dam and further reducing stability; and elevated pore water pressures increase the risk of liquefaction, causing a loss of strength and potential for failure.

Failure of Barahona No. 1 did not lead to any changes to tailings management practices or new regulations at the time. The failure of the El Cobre mine tailings dams in 1965, which killed over 200 people and caused widespread destruction and was also caused by seismic induced flow liquefaction, finally prompted the industry in Chile to act. Practitioners in Chile moved away from using the upstream method and flattened downstream slopes; regulations implementing these changes were also enacted. The failures of other tailings dams constructed using the upstream method, with notable examples in Val di Stava, Italy in 1985 and Merriespruitt, South Africa in 1994, continued to demonstrate the risks associated with constructing tailings dams using the upstream method.

References:

(2) Troncoso, J. H., Verdugo, R., & Valenzuela, L. (2017). Seismic performance of tailings sand dams in Chile. 16th World Conference on Earthquake.

(7) The Stava 1985 Foundation. (n.d.) The El Teniente tailings dam failure, 1928.

This case study was peer-reviewed by John France, PE, JWF Consulting LLC.

Lessons Learned

Dams located in seismic areas should be evaluated for liquefaction, cracking, potential fault offsets, deformations, and settlement due to seismic loading.

Learn more

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn more

Timely warning and rapid public response are critical to saving lives during a dam emergency.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- Tailings dams are always under construction until their closure. This requires on-going evaluation to adapt and respond to changing conditions.

- A strong quality and risk management system should be established and implemented for all phases of a tailings storage facility lifecycle, including closure.

Design and Evaluation of Tailings Dam, Technical Report

Design Guide for Metal and Nonmetal Tailings Disposal

Engineering and Design Manual for Coal Refuse Disposal Facilities

Global Industry Standard on Tailings Management

Planning, Design, and Analysis of Tailings Dams