Maple Grove Dam (Colorado, 1979)

The Maple Grove Dam in Lakewood, Colorado was originally constructed in 1955 as a 50 foot tall, 1,150 foot long zoned earthfill embankment dam. The dam impounded a 550 acre-foot storage reservoir and had a spillway capacity of 570 cubic feet per second (cfs). In 1960, the spillway was relocated and capacity increased to approximately 1,100 cfs. The dam is owned, operated, and maintained by the Consolidated Mutual Water Company (CMWC). A storm with an estimated annual exceedance probability (AEP) of 6.7x10−2 (1 in 15 chance) occurred in May 1973 in the Lena Gulch Drainage Basin, causing the Maple Grove spillway to discharge approximately 850 cfs. In response to that flood and in recognition of the elevated infrastructure damage and life loss potential created by recent development within the downstream drainage near the dam, CMWC was directed by the Colorado Division of Water Resources (DWR) to increase the Maple Grove Dam spillway capacity to pass the calculated “Standard Project Flood” (SPF) corresponding to approximately 50 percent of the Probable Maximum Flood (PMF). The SPF was determined to have a peak inflow rate of 13,900 cfs.

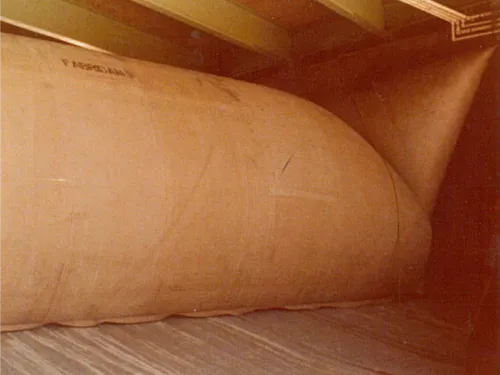

In 1975, the Urban Drainage and Flood Control District (UDFCD) recognized the unintentional flood attenuation benefits created by Maple Grove Dam for portions of Wheat Ridge, Jefferson County, and Lakewood. These municipal communities along with the CMWC and the UDFCD collaborated in 1976 to design a unique spillway enlargement that would meet the needs of both the CMWC and the flood-prone communities downstream of the reservoir. This new design included the addition of two Fabridams, one 30 foot long by 6 foot diameter and one 40 foot long by 10 foot diameter, placed within the newly enlarged spillway beneath the W. 27th Avenue bridge. The Fabridams were able to be filled with either water, air, or a combination of both and included automatic controls for ease of maintaining desired heights of both dams. The resulting design provided the UDFCD and downstream local governments with greater flood attenuation during 1x10-2 AEP (1 in 100 chance) storm events while giving the CMWC confidence the reservoir would be able to withstand the SPF without overtopping. The design was approved by the Colorado DNR State Engineer’s Office and construction of the spillway with the additions of the Fabridams was completed in August of 1977.

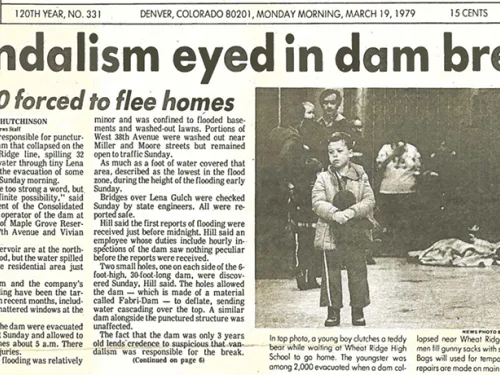

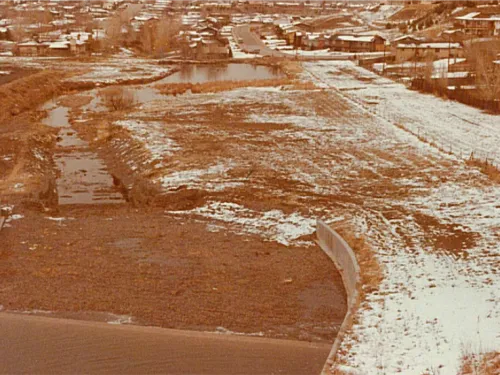

During a routine inspection of the Fabridams on March 17, 1979 around 11:45 PM, personnel of the CMWC noticed one of the Fabridams was collapsing and allowing water in the reservoir to be suddenly released down the spillway. The CMWC personnel immediately contacted the Wheat Ridge Police Department, who began evacuations of approximately 2,000 people from residential units along Lena Gulch in the 2.3 mile river reach immediately below the dam. Approximately 100 acre-feet of water was released during a period of about 2.5 to 3 hours before the spillway flows ceased, lowering the reservoir by about 3 feet. The peak flow immediately below the reservoir was estimated to be 600 cfs and caused residential basement flooding, first floor damage in some commercial buildings, bank erosion, and damage to streets and culverts. No life loss was reported and all evacuated individuals were allowed to return to their homes at 4:20 AM on March 18, 1979.

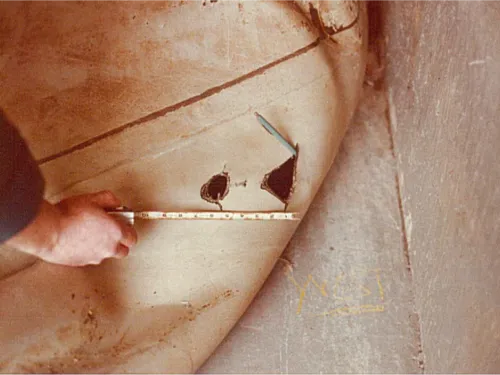

Investigations into the cause of the rupture and failure of the Fabridam highlighted a major vulnerability. A slit-type opening was found on the right side of one of the Fabridams and on the left side two additional leakage areas were discovered, one a slit-type opening and the other a circular hole. It was determined that these openings had been purposely inflicted. There was no evidence of tearing or rupture; the slits ended cleanly and the edges of the holes had the appearance of a cleanly cut surface. Additionally, the material in Fabridam installations had been in use for approximately 10 years with no history of rupturing of the material due to weathering or deterioration of the material itself. The Fabridam manufacturer’s engineer was present at the initial inspection and provided a list of several other instances similar to this one that had occurred throughout the United States. Although not common, these situations were reportedly difficult to guard against as the Fabridam material could be punctured with a sharp knife. Inspections by engineers from the Colorado DWR, the manufacturer’s representative, CMWC, UDFCD, and members of the Lakewood Department of Public Safety indicated that the cause of the dam collapse was vandalism. It was determined that to prevent future incidents of vandalism, acceptable programs of surveillance specifically of the Fabridams were needed in the interest of public safety.

Initial repair of the Fabridam consisted of patching with rubber and plastic adhesive until final repair could be made during summer months. The Fabridam was ultimately repaired by a process of co-vulcanizing which is an air-cure patching process rehabilitating the material to 95 percent of its original strength. Although this method is able to adequately repair the dam, it would not protect it from future vandalism. Recommendations were made to limit access of the public to the spillway crest where the Fabridams were located. These recommendations included adding fencing, an alarm system, more frequent personnel inspections, and a lighting system to illuminate the spillway crest. In addition, a warning system was recommended within the operating equipment to effectively notify personnel should the Fabridams have an abnormal drop in pressure for any reason.

Starting March 18, 1979, personnel surveillance was notched up to half-hour intervals without pattern. Security lighting was installed on March 27, 1979. On April 2, 1979, a seasonal changeover was made filling the Fabridam with water instead of air, a mode of operation less likely to be tampered with. On June 4, 1979, a low pressure monitor and alarm system was put into operation which activated a visual and audio alert in the treatment plant anytime the pressure system in the Fabridams operated for longer than two minutes. Alternative designs for supplying emergency power were initiated on June 14, 1979. On August 1, 1979 fencing was placed on top of the concrete walls of the spillway that included a barbed wire overhang in an effort to deter entry into the property, and a breakaway fence was erected on the downstream end of the spillway to ensure that this would lay down under flood flows. According to a letter from the Colorado Governor, the Colorado DWR had “for many years” recommended limiting or prohibiting development along the natural water course as much as possible; however, this recommendation had not been enacted. On May 14, 1980, the Colorado DWR approved the construction of an erodible earthen fuse plug type cofferdam in the spillway approach channel to assure that any unintentional deflation of the Fabridam would release only that water stored between the fuse plug and the Fabridams. Construction of the erodible fuse plug cofferdam was completed on July 16, 1980 and the fuse plug cofferdam remained in service as a precautionary measure for the duration of the life of the Fabridams.

A review committee was assembled following the event and charged with summarizing the event and evaluating the responses taken by all involved in the emergency response actions.An after-action report developed by this committee, dated May 18, 1979, summarized the conclusions of that committee. Among other conclusions, the report states the following, which highlights the need for improved emergency action planning by all agencies involved:

“Communications during the emergency were adequate for each organization involved, but between organizations were marginal at best. There is no clear plan as to who is in charge during an emergency, and during an intergovernmental emergency situation the plans are even less clear.”

In 2004, the Fabridams in the Maple Grove Reservoir were reaching the end of their service life. A replacement system was put in place that uses hydraulic cylinders to raise and lower two independent steel crest gates. They operate under the same discharge parameters as did the Fabridams, but are less susceptible to vandalism and are simpler to operate and maintain than the Fabridams were, allowing greater confidence in the integrity of Maple Grove Dam and ultimately a safer option for the public. These gates have operated successfully since original installation but still require reliance on mechanical systems and human intervention to safely pass large floods. As such, the CMWC and UDFCD initiated an exploratory project in 2017 to develop and evaluate alternatives for completely eliminating spillway gates from the Maple Grove Dam.

References:

(1) The Consolidated Mutual Water Company Meeting Records, News articles, Correspondence. (1979).

(2) Hutchinson, Paul. (1979). Vandalism eyed in dam break. Rocky Mountain News.

(3) Newman, Karen. (1979). Three holes cut in dam, probe finds. Rocky Mountain News.

(4) State of Colorado Division of Water Resources, Dam Inspection Reports, Correspondence, Construction Records

(5) State of Colorado Department of Law Litigation Case Records.

This case study summary was peer-reviewed by Gregory Richards, P.E., CFM, Gannett Fleming, Inc.

Lessons Learned

Dam incidents and failures can fundamentally be attributed to human factors.

Learn more

Emergency Action Plans can save lives and must be updated, understood, and practiced regularly to be effective.

Learn more

Intervention can stop or minimize consequences of a dam failure. Warning signs should not be ignored.

Learn more

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn more

Site security is a critical aspect of dam safety that shouldn't be overlooked or disregarded.

Learn more

The hazard classification of a dam can change over time (hazard creep).

Learn more

Timely warning and rapid public response are critical to saving lives during a dam emergency.

Learn more

Dams Sector Active and Passive Vehicle Barriers Guide

Dams Sector Crisis Management Handbook

Dams Sector Cybersecurity Program Guidance

Dams Sector Personnel Screening Guide for Owners and Operators

Dams Sector Waterside Barriers Guide

Dams Sector-Specific Plan: An Annex to the NIPP 2013