Taum Sauk Dam (Missouri, 2005)

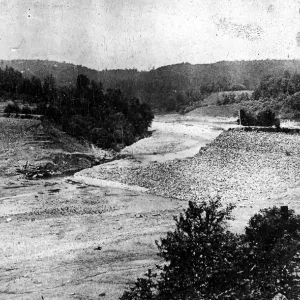

Taum Sauk Pump Storage Plant was constructed by Union Electric in Reynolds County, Missouri between 1960 and 1962 to provide a means of hydroelectric power generation during peak demand periods. The plant consisted of an Upper Reservoir situated atop Proffit Mountain contained by a kidney-shaped rockfill dike, a Lower Reservoir and Powerhouse impounded by a concrete gravity dam, and a 7,000-foot-long concrete and steel-lined tunnel that connected the two. On December 14, 2005, the Upper Reservoir of the Taum Sauk Pump Storage Plant failed by overtopping during the final minutes of one of its pumping cycles. As a result, the reservoir’s 4,300 acre-feet volume of stored water was released from a 656-foot-wide breach in 25 minutes, traveling down Proffit Mountain toward the Black River with a peak discharge of 273,000 cfs. Before it reached the river and flowed into the Lower Reservoir where it was entirely contained, the flood destroyed 281 acres of Johnson’s Shut-Ins State Park and ripped the superintendent’s home from its base. By chance alone, loss of life was averted and only four people sustained injuries as a result of the Upper Reservoir failure. However, estimates of the destruction and property damage caused by the failure and ensuing flood have reached $1 billion.

"Overflowing of the upper reservoir is obviously an absolute ‘NO-NO’…The dam would severely erode and cause eventual failure of the dam…If water continued to spill over the top of the wall, it could cause a section to collapse and then it would be all downhill from there – literally.” - Email from plant operator to supervisors; September 27, 2005

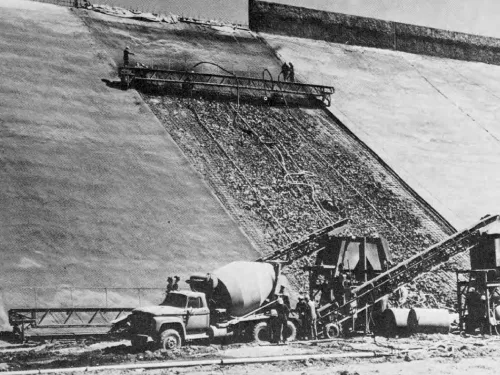

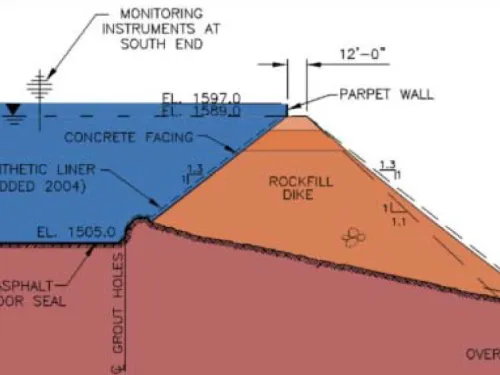

Located approximately 6 miles north of the town of Lesterville and 1 mile east of the Black River, the Upper Reservoir reached a maximum height of 90 feet, excluding the 10-foot-high reinforced concrete parapet wall that supplemented the 6,562 foot perimeter of the dike. During the construction of the Upper Reservoir, excavated material from Proffit Mountain provided the dumped, uncompacted rockfill that formed the dike. The inside of the reservoir was lined with shotcrete. Because no spillway system was incorporated into the original design, the dike was equipped with two float type actuator systems as primary and secondary pump shutdown systems to stop the facilities’ two pumps should the water in the reservoir exceed the desired level. The Upper Reservoir was the first hydroelectric facility worldwide capable of remote control that did not require system operation personnel on site.

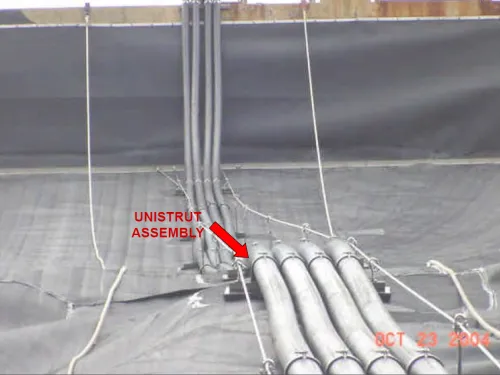

In 2004, a geomembrane liner was installed inside the reservoir to control the leakage within the dike that resulted from cracks in the thin layer of shotcrete caused by differential settlement the dike had experienced during its 40 years of operation. During the installation of the liner, the pump shutdown mechanisms were revised. The new system consisted of three pressure transducers in high density polyethylene (HDPE) pipes anchored to the concrete layer with a programmable logic controller to initiate shutdown if necessary.

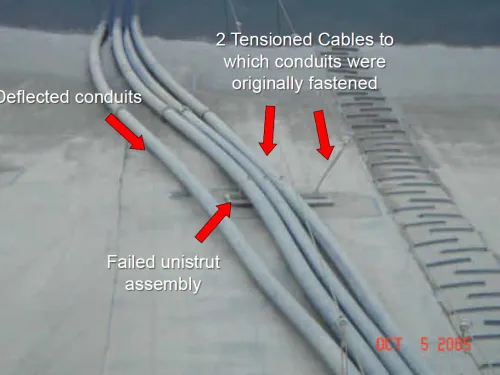

On Sunday, September 25, 2005, the day before the Taum Sauk Plant would receive an Institute of Electrical and Electronics Engineers (IEEE) award for innovation, several AmerenUE (formerly Union Electric) representatives visited the Upper Reservoir. To their surprise, they noticed water pouring over one of the edges of the dike in a manner that resembled “Niagara Falls.” System operators immediately worked to manually disable the pumps and control the water level, averting disaster. When divers subsequently investigated the possible cause of the overflow, they determined that several of the HDPE transducer-housing conduits had become detached from their original and intended positions. As a result, the pressure transducers’ ability to report accurate water levels was hindered, and lower water levels were being recorded than actually existed. Until repairs on these deflected conduits could be properly executed, several precautionary measures were taken. First, the system programming was altered to report the water level within the reservoir lower than the instrument’s actual readings, in order to avoid the false positive measurements that the pressure transducers were reporting. Secondly, “fail safe” Warrick probes were attached to the inner reservoir rim as backup sensors that would automatically and completely shut down the pumping system if the water level within the reservoir reached their height.

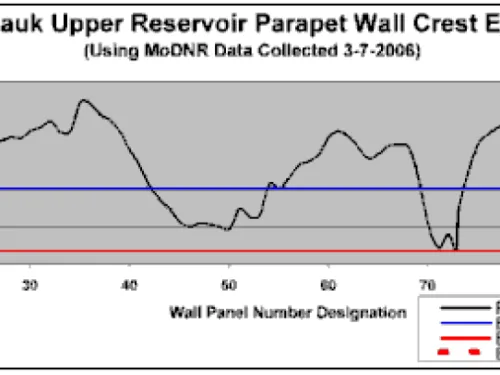

On December 14, 2005, near the end of the morning pumping cycle, both the primary reservoir sensors and the “fail safe” Warrick probes failed to report the critical high water level in the reservoir because the probes had been incorrectly set at a higher elevation than the low point on the parapet. This was further compounded by system programming that required both probes to trip the pumps off-line. There was no program in place to maintain calibration of the sensors against actual reservoir levels, and no program to evaluate the actual crest elevation around the reservoir rim with respect to shut down triggers within the system programming. Later investigations into the failure revealed that overflow at the northwest section of the dike began at 5:09 A.M. Flow over the parapet wall of the Upper Reservoir during failure resembled that over a broad crested weir and initially fell on the three feet of outboard wall footing that surrounded the dike. As the depth of water in the reservoir increased the trajectory of the nappe shifted further away from the reservoir, eroding the exposed and unprotected rockfill embankment beneath the parapet wall.

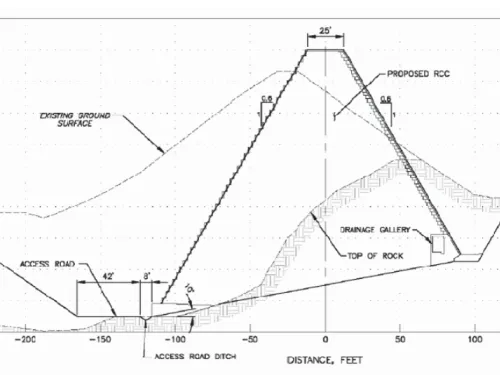

Continued erosion of the embankment ultimately led to the 656-foot-wide breach in the dike, which emptied the entire reservoir. Construction of a new Upper Reservoir for the Taum Sauk Pump Storage Plant took place from 2007 to 2010. Today the reservoir is impounded by a roller-compacted concrete dam that is equipped with a multitude of safety features and appurtenances that adhere to current standards.

References:

(2) Hollenkamp, T., Giesmann, C., & Frerking, M. (2011). Case History Summary: Taum Sauk Storage Dam Failure, Lessons Learned, and the Rebuild. Canadian Dam Association Bulletin, 22(4), 16-25.

(3) Rizzo, P., Rizzo, C., & Bowen, J. (2011). Lessons Learned at the Taum Sauk Rebuild. USSD 2011 Annual Conference Proceedings. United States Society on Dams.

(5) FEMA. (n.d.). Taum Sauk Project [Presentation]. Dam Failures and Lessons Learned Seminar.

Lessons Learned

Dam incidents and failures can fundamentally be attributed to human factors.

Learn more

Downstream flooding can be caused by spillway flows that exceed channel capacity or as a result of reservoir misoperation.

Learn more

Forensic investigations are needed for major dam failures and incidents in order to determine the history of the contributing physical and human factors, and the culminating physical failure modes and mechanisms.

Learn more

Intervention can stop or minimize consequences of a dam failure. Warning signs should not be ignored.

Learn more

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- Many years of successful dam performance does not guarantee future successful performance.

- Pumped storage embankment dams should have an emergency spillway or other redundant features to prevent overfilling and overtopping of the embankment.

- Settlement of earthfill embankment dams can reduce freeboard and increase the risk for overtopping. New embankment dams should be designed with allowances for settlement.

Case History Summary: Taum Sauk Storage Dam Failure, Lessons Learned, and the Rebuild

Delivering Benefits through Evidence: Lessons from Historical Dam Incidents

Overview of the Taum Sauk Pumped Storage Power Plant Upper Reservoir Failure, Reynolds County, MO

Report of Findings on the Overtopping and Embankment Breach of the Upper Dam - Taum Sauk Pumped Storage Project, FERC No. 2277

Risk Estimates for Operational Failure

Additional Resources not Available for Download

- ASDSO. Taum Sauk Project. Dam Failures and Lessons Learned Seminar. Denver: Federal Emergency Management Agency.