Camará Dam (Brazil, 2004)

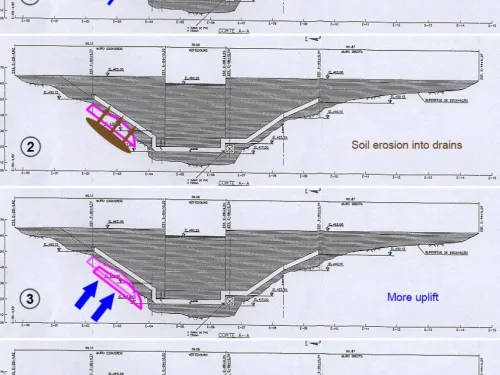

Camará Dam is a roller compacted concrete (RCC) dam in Brazil completed in 2002 and failed during first filling in 2004. The dam was originally designed as an earthen embankment, but the design changed to RCC after the contractor was selected. Irregularities and potential conflicts of interest in the contracting process were allowed by the dam owner. The left abutment was excavated to competent gneissic migmatite rock and an upstream-downstream zone of poor-quality rock near the dam toe was excavated and backfilled with concrete. Unfortunately, the geology was very complex, and an unforeseen geological feature/fault existed which extended up the left abutment about 16 feet (5 meters) below the exposed rock surface creating a weak plane under the whole left side of the dam. During a large rainstorm, the reservoir rose to a new record level but still at least 20 feet (6 meters) below the spillway crest (67% of capacity). Excessive leakage was observed from the drainage gallery relief drains, which ceased flowing when the drains became plugged with material being washed away from the foundation. This pushed the full reservoir head deeper into the foundation, resulting in delamination of the abutment rock. The dam failed when a portion of the concrete fractured and blew out like a huge concrete plug. The investigation uncovered problems with design, construction, oversight, and monitoring ultimately leading to the state-level dam owner being held liable for lack of maintenance and construction oversight.

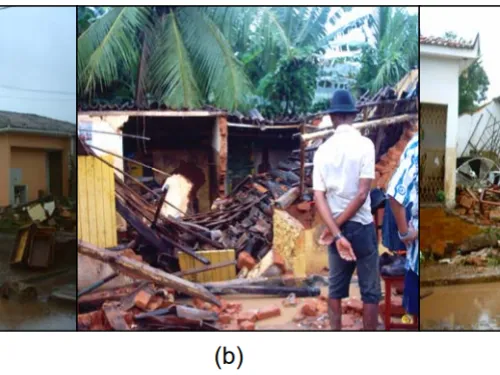

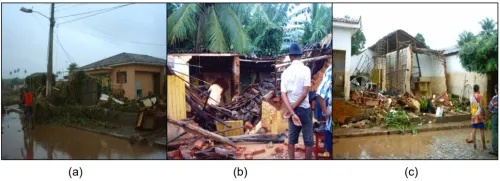

The breach drained the reservoir and inundated the city of Alagoa Grande and vicinity along the Riachão and Mamanguape Rivers, resulting in five fatalities, 3,300 people left homeless, and almost four million dollars in damage at the time.

No single error can be cited as the cause of the dam failure. Instead, like many catastrophic events, it was a series of poor decisions and adverse conditions that contributed to the dam failing. Trouble began before any construction equipment was mobilized. As the dam was owned by the State of Paraiba, Secretariat for Infrastructure and Water Resources, its construction and failure became a contentious political and legal issue for years later.

Design and Construction

The dam was designed to provide water supply for nearby towns and agriculture by Holanda Engenharia Ltda., a small Brazilian engineering consultant with experience in concrete hydraulic structures. A geologic survey in 1997 uncovered complex geology in the left abutment that would require treatment, namely a shear zone filled with weathered gneissic migmatite rock and soil. The geologic investigation was deemed in accordance with best practice and included a fully mapped abutment surface, 7 rotary borings, water loss tests and experimental grouting. The preliminary design called for an earthfill embankment on bedrock foundation, built across the narrow valley. A design-build construction contract was awarded to a single contractor, CRE Engenharia Ltda, who began clearing the foundation in 2000. When the rock foundation was exposed, the shear zone was larger than expected. The biggest concern was that a larger embankment dam would be required to deal with the shear zone leading to a larger site and increased environmental impact. An RCC dam was proposed as an alternate design keeping the footprint small. The contractor didn’t have experience with RCC and so requested that a joint venture be allowed despite this being prohibited by the contract [2]. The second contractor in the venture was Andrade Galvão Engenharia Ltda. The contract change was allowed, as were other deviations to the contracting process including: a price increase from $R9 to $R15 and finally $R24 Million Reals ($5 to $8.2 to $13.4 million in year 2000 US dollars)[5] , and the contractor being allowed to hire construction inspectors to perform quality control. This important task was handed to Holanda Engenharia Ltda, the design consultant. The potential conflict of interest was not addressed. In fact, the State dam owner provided little oversight during construction which the joint venture completed in 2002.

During foundation clearing, an upstream to downstream shear zone filled with weathered rock and soil was uncovered low in the left abutment. The shear zone was excavated but visual investigation was difficult because the fracture zone extended into the abutment at a steeply inclined angle. Soil was excavated approximately 3 meters into the abutment where the shear zone thickness seemed to taper off. The treatment consisted of a conventional concrete gravity wall extending partially under the overhang and backfilled by injection grouting drilled from above. The excavation was limited to within the dam footprint, possibly leaving some poor-quality material in the abutment at the edges of the dam. After the foundation was cleared, no further borings were taken in the abutment to determine the depth or continuity of the poor-quality rock zone. Foundation clearing did not extend beyond the immediate work area of the dam-abutment contact.

In retrospect, they severely underestimated the continuity of the shear zone which extended as a steeply inclined, plane of weakness under nearly the entire left abutment, covered by roughly 10-16 feet (3-5 meters) of sound rock. Its variable thickness was due to quartz dike intrusions seen clearly in the smooth failure surface. Litigants from both sides of the table agreed that the extent of the shear zone was unforeseen and unpredictable.

Another contributing factor to the failure was poor quality concrete. The RCC dam was designed with a conventional concrete upstream face to limit seepage with a thickness of at least 7.9-19.7 inches (20-50 cm). In practice that tolerance was not kept, resulting in much higher permeability than expected through the dam as evidenced by wet spots on the face near pool level [2]. The upstream face concrete had irregularities and failed to meet strength requirements in some tests [2]. Concrete testing was generally insufficient, and when it revealed strength deficiencies, they were not corrected. Consolidation grouting was done in the foundation, but proved to be insufficient due to the unforeseen extent of the shear zone. Although problematic, the concrete deficiencies were not viewed as a primary cause of the failure.

Event

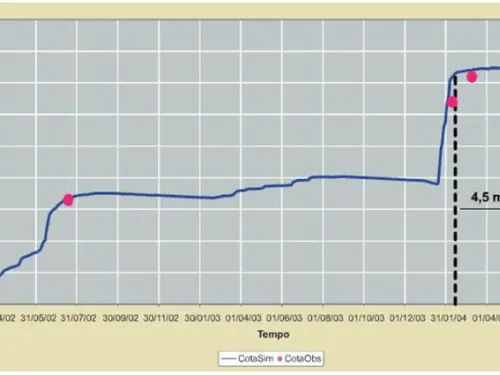

The previous two years had been fairly dry, so the reservoir had not yet reached its normal operating level. Normal to wet conditions returned in late-December 2003 to early January 2004 with a series of storms that raised the pool. In March, seepage was first observed along the left groin. The drains were flowing at a high rate and passing sediment until May 2004 when the deposition clogged the drain outlet and flooded the lower gallery. This dramatically slowed the outflow and likely raised foundation pressures. A decision was made to provide an alternate outlet from the gallery. Onsite technicians also suggested opening the dam outlet valve to lower the pool and investigate the seepage cause, but this life-saving advice was not heeded. Instead, the pool continued to rise through June 17, 2004, to El. 1491.12 feet (454.5 meters) (still 22 feet [6.7 meters] below the spillway crest).

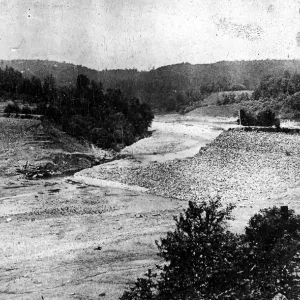

The foundation seepage and sediment migration had removed much of the soil in the left abutment shear zone reducing the stability of the overlying foundation blocks. At about 7:15 PM on June 17, experts speculate that a downstream section of the abutment delaminated and fell. This removed support for the left side of the dam which leaned forward and allowed higher pressures into the foundation, abutment and cracks in the dam. The dam failed rapidly when about 6 to 10 feet (2 to 3 meters) of rock sheared off the left abutment and took with it a section of the RCC dam from roughly El. 1377.95 feet (420m) to 1487.86 feet (453.5m), leaving a diagonal, rhombic-shaped hole roughly 23 to 46 feet (7 to 14 meters) wide and 98 feet (30 meters) tall [1, 6].

The reservoir drained quickly peaking at an estimated 85,000 – 106,000 cfs (2,400-3,000 cubic meters per second) [8]. Eleven days after the failure, the remaining arch of dam collapsed into the breach. Thankfully the site had been secured from the many onlookers by police and there were no additional fatalities.

Impacts

The sound of concrete cracking was heard like an explosion by nearby residents who sounded the alarm to downstream communities. All was quiet in Alagoa Grande, the closest city to the dam, where the power had just gone out. A radio station broadcast the warning and many people received calls from family and friends, but it was not fast enough. The flood swept down the Riachão River and into the Mamanguape River causing economic and environmental damage for at least 30 miles (48 km). In Alagoa Grande 12 miles (19 km) downstream, the flood rapidly raised the river level by 16 feet (5 meters). It destroyed roads and bridges, damaged houses, businesses, crops and resulted in 5 deaths and over 3,300 left homeless [3]. As the flood traveled down to Mulungu and other towns, the warning had been sufficient to avoid any further fatalities.

The failure of Camará Dam and other notable dam failures with fatalities prompted new legislation in Brazil to bring more order to the country's dam safety industry. Regulation of dam safety had not been consistently enforced due to a lack of laws providing clear jurisdiction and authority. Camará Dam is not on a “Federal River” where ANA has national jurisdiction, so it falls to the AESA who oversees State government dam owners [8].

The Paraiba State Attorney General sued the state as dam owner and the contractors to reimburse the victims for their losses and to rebuild the dam. In 2011, a judge found the state was liable due to failures in construction oversight, maintenance, and inspection. They were ordered to rebuild the dam and reimburse victims for their losses. The state appealed, seeking to also hold the construction companies liable for poor quality construction. In 2013, the State of Paraiba Appeals Court upheld the previous ruling finding the state solely liable and releasing the companies from claims. It was appealed to the Federal court which upheld the ruling in 2023.

Reconstruction

In 2011 the state began the reconstruction process by putting the contract out for bid. Two bids were received including the original contractor who won the contract for another $R18 million. After an investigation into the bidding process, the original company was allowed to rebuild the dam, completing it in 2016.

The left section of the dam was deconstructed up to the spillway and the toe of the dam removed to accommodate new construction. Conventional concrete was selected instead of RCC. The new dam was designed with a shear key on the downstream toe of dam, a grout curtain was installed, the drainage system was refurbished (enlarged and filtered), instrumentation was installed which consisted of piezometers, multi-rod extensometers, and drainage flow control system devices. First filling started in June 2017 and is ongoing. It is being monitored on a monthly basis according to the new Operation, Maintenance and Surveillance manual.

The Camará Dam failure was one in a string of notable dam failures from 2003-2009 which led to new dam safety legislation in 2010 seeking to define minimum requirements, jurisdictions, and oversight which had been confusing and inconsistent. Responsible agencies responded with updated guidance resolutions. The law was updated in 2020 to incorporate tailings dams and strengthen other provisions [8].

References:

(1) Kanji, M.A. (2004). Parecer Técnico Sobre as Causas da Ruptura da Barragem Camará [Technical Report on the Causes of the Failure of Camará Dam].

(2) Perazzo Barbosa, N., Vieira Mendonça, A. & Carvalho, L.H. (2005). A Construção Da Barragem Barra Do Camará e Seu Acidente [The Construction of Barra Do Camará Dam and its Accident]. Proceedings of the 26th National Conference on Large Dams. Brazilian Committee on Dams.

(3) Paiva Junior, H.B. (2006). Efeitos Do Rompimento Da Barragem De Camará Na Área Urbana Do Município De Alagoa Grande – PB [Effects of the Camará Dam Collapse on the Alagoa Grande, Paraíba Urban Area].

(4) Pimentel, S. (2004). Brazil: Picking up the Pieces After Tragic Deluge. News from Brazil, Agencía Brasil. (Translated from Portuguese by Allen Bennett).

(7) Mello, F.M., Sandroni, S.S. & Guidicini, G. (2021). Lições Aprendidas com Acidentes e Incidents em Barragens e Obras Anexas no Brasil [Lessons Learned from Accidents and Incidents in Dams and Related Works in Brazil]. Brazilian Committee on Dams.

(8) Dorostkar, A., Lobato, L., Risher, P. & Tabet, J. (2024). "Camará Dam Failure 20 Years Later – New and Improved." 2019 ASDSO Annual Conference Proceedings. Association of State Dam Safety Officials.

This case study summary was peer-reviewed by Juliana Tabet, C.PEng, ENMAX; Abbas Dorostkar, PhD., PE, Pacific Gas & Electric Company; and Cassandra Wagner, P.G., US Army Corps of Engineers.

Lessons Learned

Concrete gravity dams should be evaluated to accommodate full uplift.

Learn more

Dam incidents and failures can fundamentally be attributed to human factors.

Learn more

Forensic investigations are needed for major dam failures and incidents in order to determine the history of the contributing physical and human factors, and the culminating physical failure modes and mechanisms.

Learn more

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn more

Stability of the dam foundation and other geologic features must be considered during dam design.

Learn more

The first filling of a reservoir should be planned, controlled, and monitored.

Learn more

Risk Management - Best Practices and Risk Methodology

Roller-Compacted Concrete, EM 1110-2-2006

Seepage Analysis and Control for Dams, EM 1110-2-1901

Stability Analysis of Concrete Structures, EM 1110-2-2100