Penn Forest Dam (Pennsylvania, 1994)

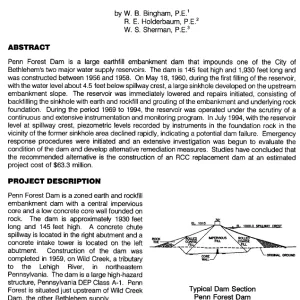

Penn Forest Dam was constructed between 1956 and 1958 to be one of the main water supply reservoirs for the city of Bethlehem, Pennsylvania. The dam was originally an earthfill embankment structure, standing 145 feet high, 1,930 feet long, and storing 6.4 billion gallons of water.

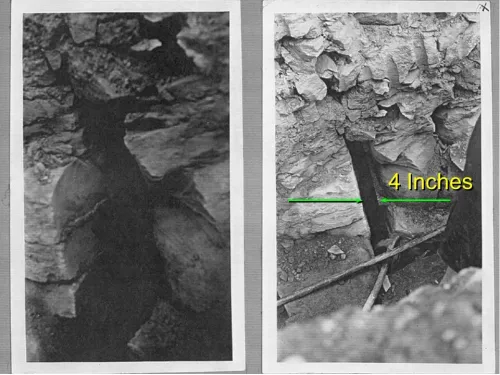

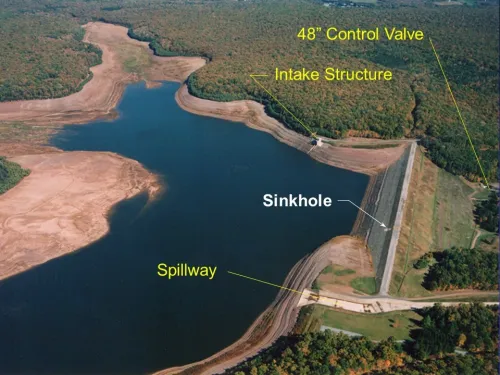

Almost immediately after its completion, the dam began experiencing problems. As the water rose within 4.5 feet of the spillway crest during the first filling in 1960, approximately 350 gallons per minute (gpm) of seepage began flowing from a road immediately downstream of the dam. Just one month later, a large sinkhole (15 feet in diameter and more than 15 feet deep) developed on the upstream slope of the dam. The water level in the reservoir was lowered immediately, and the sinkhole was repaired by backfilling with earth and rockfill and covered with concrete bags. Although the fill had very little effect on the leakage, the lowered reservoir level reduced seepage to about 90 gpm. Initial repairs consisted of grouting the underlying foundation rock in the vicinity of the sinkhole and pressure injecting surface-hydrated bentonite lumps and cellophane strips in the embankment to fill the voids. During drilling for grouting, voids were encountered in the embankment up to 18 inches in diameter. The grouting program did not significantly reduce the measurable seepage emerging from the areas at and downstream of the toe of the dam.

Further investigations were performed and additional professional opinions from several engineering consultants were sought to determine the next course of action. There was general concurrence that the failure mechanism was piping of the embankment materials into the fractured rock foundation. Numerous concerns were expressed regarding the original design, construction, and emergency repairs. A controlled filling program was implemented in 1964 after installation of numerous embankment and foundation instruments consisting of 275 piezometers, several weirs to monitor seepage, and a network of survey monuments on the embankment.

The reservoir was slowly raised to the spillway crest from 1964 to 1969, almost 10 years after the dam was first constructed. With a full reservoir behind the dam, aggregate seepage was measured to be around 450 gpm. Because distrust in the dam structure still remained, Penn Forest Dam was operated under intensive scrutiny and exhaustive instrumentation and monitoring from 1969 until 1994. Near the end of this period, the monitoring program was scaled back and consisted of reading approximately 184 instruments on a biweekly basis, including five seepage weirs and two seepage flumes. Piezometer levels and rates of seepage were measured regularly and several smaller remedial actions were taken to ensure the condition of the dam did not deteriorate.

In July 1994, while the reservoir was filled to capacity, piezometric levels suddenly declined 10 to 20 feet in the vicinity of the original sinkhole location from 1960. At first, the drop was overlooked as it coincided with a planned reservoir drawdown, but eventually the changes in the piezometer levels were interpreted as a possible early warning sign of recurrence of piping. The seepage records showed that the total seepage increased to over 900 gpm which further indicated the dam was deteriorating.

Emergency response procedures were enacted immediately, requiring 24-hour surveillance, daily piezometer and weir readings, and lowering of the reservoir two feet per day. Emergency supplies were also stockpiled and notifications were sent to the proper authorities in case of a dam failure. These emergency response measures remained in effect until January 1995, when the pool had been drawn down to a safe level 25 feet below the spillway crest.

Over the next several months, thorough investigations were initiated to determine the integrity and safety of the dam going forward. The investigations confirmed that the original sinkhole failure had been caused by a combination of design and construction defects. It led to massive seepage and erosion of material from within the embankment. Failure was initiated by flow into the foundation from the reservoir area and through cracks in the embankment entering open rock fractures. The dam had no design features to prevent erosion from progressing to the point of failure. The detailed investigations identified the following primary defects in the dam:

- The original foundation grouting program was ineffective.

- The dam was constructed without internal filter drains.

- The abutments of the dam were not adequately prepared.

- The dam foundation was not adequately prepared.

- Poor quality control during construction.

Investigations also concluded that the low-cost, high-risk repair methods completed in 1960 to prevent the failure of Penn Forest Dam would not be appropriate today. Consequently, the defects which had caused the initial failure were still present, and represented high long-term risks. Furthermore, it was determined that the deficient zones within the dam foundation and embankment were not limited to the original sinkhole. There were clear indications of seriously deteriorating conditions and warning signs of a developing dam failure. The most fundamental requirement was to essentially eliminate seepage through the embankment and foundation.

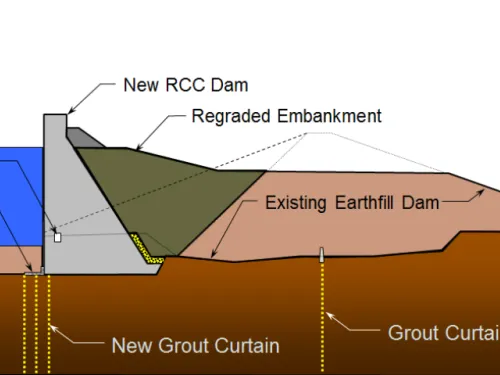

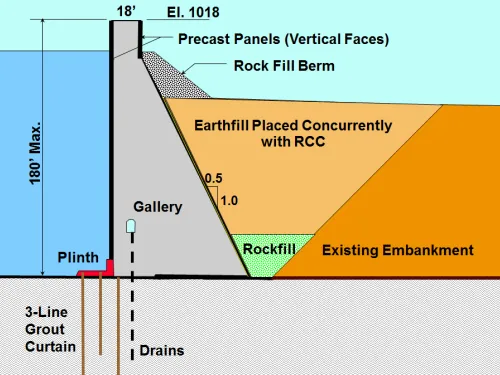

The condition of the dam was such that it warranted a major repair and/or reconstruction of the dam. From the options presented, the best option was to construct a new roller-compacted concrete (RCC) dam that would be able to restore the reservoir to its original operating level. The new RCC structure was completed in 1998. The RCC dam required approximately 380,000 cubic yards of roller-compacted concrete to build, making it the third largest RCC dam in the U.S at the time.

References:

Lessons Learned

All dams need an operable means of drawing down the reservoir.

Learn more

Dams should be thoroughly assessed for risk using a periodic risk review process including a site inspection, review of original design/construction/performance, and analysis of potential failure modes and consequences of failure.

Learn more

High and significant hazard embankment dams should have internal filter and seepage collection systems.

Learn more

Intervention can stop or minimize consequences of a dam failure. Warning signs should not be ignored.

Learn more

Regular operation, maintenance, and inspection of dams is important to the early detection and prevention of dam failure.

Learn more

The first filling of a reservoir should be planned, controlled, and monitored.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- High and significant hazard embankment dams should have internal filter and seepage collection systems.

- In emergency situations, lowering the reservoir can be an effective means of risk reduction.

- Internal erosion can take decades to progress.

Replacement of a Deteriorated Earthfill Dam with an RCC Gravity Dam

Replacement of a Deteriorated Earthfill Dam with an RCC Gravity Dam