Drum gates are complex mechanical systems that must be carefully operated and maintained.

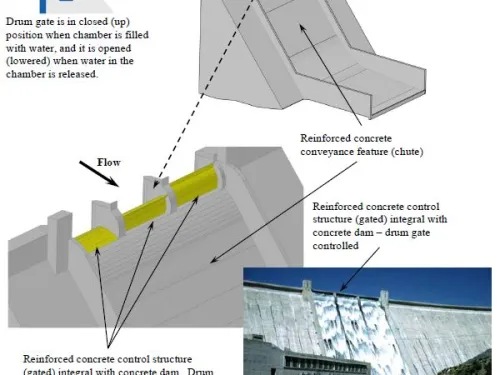

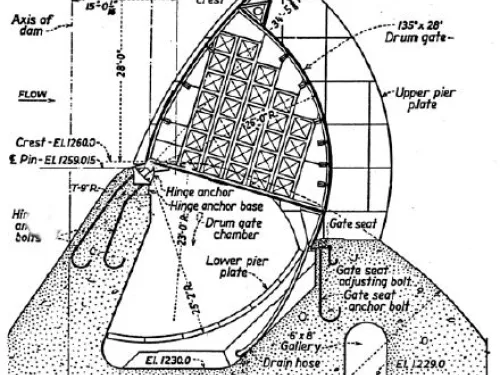

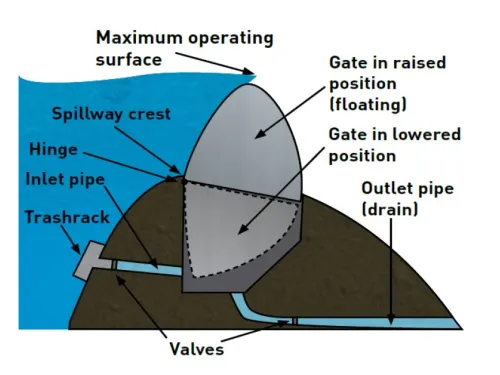

A typical drum gate consists of a hollow steel structure (drum), hinged on either the upstream or downstream side, that is operated using the principle of buoyancy. The drum is formed by skinplates reinforced by internal bracing. In the closed (up/raised) position, the self-weight of the drum gate is overcome by buoyancy forces from water contained within a float chamber beneath the drum composed of reinforced concrete. This chamber is filled via an upstream intake and series of valving and other piping. Internal drains prevent the drum interior from filling with leakage, which would reduce buoyancy. To initiate spillway flows, the gate is moved to the open (down/lowered) position by releasing water from within the float chamber through drain lines and valves. Flows into and out of the float chamber can be controlled by manually operated or automated valve control systems. Gate seals prevent excess leakage around the gates, while gate stops, or seats, prevent the gate from over rotating.

Within the United States, a number of federal and non-federal owners have dams equipped with drum gates. The U.S. Bureau of Reclamation (Reclamation) currently operates nine facilities that fall under this category, including notably Hoover Dam (Nevada/Arizona), Grand Coulee Dam (Washington), and Shasta Dam (California). The United States Army Corps of Engineers (USACE) operates Sepulveda Dam (California) near Los Angeles. Elsewhere in California, there are also a number of dams equipped with drum gates operated by non-federal owners. These include Rock Creek, Cresta, and Pit No. 4 Dams (Pacific Gas & Electric Company [PG&E]), Early Intake and O’Shaughnessy Dams (San Francisco Public Utilities Commission), Morris Dam (Los Angeles County Public Works), and Florence Lake Dam (Southern California Edison).

International examples of dams equipped with drum gates include Cleveland Dam (Canada), Liapootah Dam (Tasmania), Pitlochry Dam (United Kingdom), Little Nerang and Warragamba Dams (Australia), and Madden Dam (Panama).

There have been at least eight documented incidents involving drum gates as summarized below.

- Hoover Dam (Reclamation), Nevada/Arizona, USA, 1941. An unexplained lowering occurred of at least one drum gate on the Arizona side, resulting in an estimated release of 38,000 cubic feet per second (cfs). No injuries or fatalities were reported.

- Guernsey Dam (Reclamation), Wyoming, USA, 1986. One of two drum gates inadvertently opened when a painting contractor left trash within the gate interior, which eventually plugged the drain line. The interior of the gate filled with water, causing the gate to lose buoyancy and resulting in a partial opening of the gate. Although there was a significant increase in downstream discharge, the downstream channel capacity was sufficient to contain the release and no injuries or fatalities were reported.

- Cresta Dam (PG&E), California, USA, 1997. During the busy July 4th weekend, one of two drum gates failed, causing river stage to increase 13.5-feet over a 40-minute period at a location approximately 1-mile downstream from the dam, with a maximum downstream discharge of over 15,000 cfs (relative to the peak historic discharge of 115,000 cfs on January 1, 1997). Mean daily flows in the days prior to the incident were approximately 70 cfs. An investigation into the failure determined that the drum gate lowered inadvertently primarily due to a combination of failure of the gate interior drain line in addition to leakage into the drum gate itself. The were no impacts to downstream structures or roadways; however, several recreationists were affected (including two who had to be rescued by helicopter). There were no injuries or fatalities.

- Black Canyon Diversion Dam (Reclamation), Idaho, USA, 1998. During a routine exercise of the drum gates, one of three gates was lowered roughly 1.5 feet, but attempts to raise the gate failed. The gate was further lowered another 6 inches and again could not be raised. After reservoir lowering, an issue with one of the drain lines was discovered and repaired. It was determined that the gate did not lower (open) entirely because a check valve closed or the drain line on the opposite end of the gate interior passed enough water to maintain equilibrium. No injuries or fatalities resulted from this incident.

- Black Canyon Diversion Dam (Reclamation), Idaho, USA, 2001. During routine maintenance and observation, it was discovered that 13 of the 17 3-inch diameter hinge pins in Gate No. 3 were fractured. The bushings were re-bored, re-aligned and the pins were replaced. The fractured pins did not result in mis-operation of the gates. Note that only one hinge pin in each of the other two gates was found to be fractured.

- Cleveland Dam (Metro Vancouver), Vancouver, British Columbia, Canada, 2020. On October 1, 2020, the single drum gate at the dam opened unexpectedly during maintenance activities, causing an unplanned release and sudden surge in downstream river level. The clearest contributing factor to the malfunction was determined to be human error related to programming of the gate control system. The incident resulted in one confirmed fatality with another individual missing and presumed dead.

- Cleveland Dam (Metro Vancouver), Vancouver, British Columbia, Canada, 2001. Previously in 2001, a similar incident occurred when the drum gate inadvertently opened resulting in high flows that trapped four fishermen; no fatalities were reported.

- Rock Creek Dam (PG&E), California, USA, 2016. In early March 2016, a large storm with moderate to heavy rainfall introduced an appreciable debris load into the Feather River basin upstream of Rock Creek Dam. Both drum gates lowered to the full-open position and failed to regulate increased river flows during the storm event. River stage below Rock Creek Dam peaked to roughly 27,000 cfs after the incident, relative to an average flow of 15,800 cfs prior to the incident. The increased releases were regulated by manually operating the drum gates at Cresta Dam, just downstream. No flooding, damage, or other adverse impacts were reported. After further testing and evaluation, it was determined that a large debris load had collected on the trash rack protecting the drum gate intake. Although there were no equipment malfunctions and the drum gates operated as designed when the trash rack became plugged, the incident resulted in further near- and long-term corrective actions to increase system reliability. This include installation of a differential pressure alarm as an indication of potential clogging of the trash rack.

In addition to the incidents noted above, there is a well-known history of operational issues and other vulnerabilities associated with drum gates. Typical concerns for drum gates include inadvertent lowering due to equipment failure or human error, puncture of the drum due to debris or rockfall, and damage due to seismic loading.

Several dams with drum gates have also been impacted by alkali-silica-reaction (ASR) deterioration. For example, two of three drum gates at Reclamation’s Friant Dam (California) were replaced by Obermeyer crest gates due to ASR-induced expansion of spillway concrete causing gate binding issues.

Recent increased impacts related to climate change and wildfire events have caused additional sediment to enter reservoirs. Sedimentation and debris loading are problematic to dam facilities and equipment, particularly for run-of-river facilities with low spillway crests relative to normal water levels. More specifically, sedimentation and debris clogging of the drum gate intake system can be problematic to drum gate operations. When the intake is clogged with sediment and/or debris, water will not be allowed to pass back into the float chamber once the drum gate is lowered, leaving the drum gate in an open position. Also, sedimentation buildup within the float chamber may cause damage to the drum gate piping drain lines located within the float chamber. Damage to the piping within the float chamber may cause water to build up within the interior of the drum gate affecting the buoyancy of the gate. Lack of water may also present an issue for regular gate testing. Filling of the drum gate float chambers is accomplished through headwater pressure from the upstream reservoir, thus if reservoir levels are too low to provide adequate inflows (or are below the intake level entirely), the gates cannot be raised fully to demonstrate satisfactory operation in the event of a flood emergency. This can make completing regular testing of gate operation difficult, or require advance planning to take advantage of the necessary reservoir conditions.

Best practice documents such as “Water Control Gates – Guidelines for Inspection and Evaluation”, published by the American Society of Civil Engineers, as well as “Best Practices in Dam and Levee Safety Risk Analysis”, published jointly by Reclamation and USACE, discuss many of the known vulnerabilities in greater detail. These resources also provide useful guidance on accounting for known issues in the context of planning for operations and maintenance, as well as in evaluating risks associated with gate operation.

Given the information presented above, three key takeaways are presented for consideration by dam owners, regulators, and others in the dam safety industry who work with drum gates.

- Operation and Maintenance. Due to the complex nature of most drum gate installations, robust operations and maintenance programs are required to ensure reliable operation of the gates and their associated systems. These programs need to be well documented in order to capture the maintenance history for each gate and ensure institutional knowledge of gate operation is maintained. For the entire life of the drum gate, operation and maintenance programs should include annual activities and cycled activities (activities scheduled to be performed every 5 to 10 years). These activities include routine inspection and visual observations, regular gate testing/cycling, annual maintenance activities (e.g., inspection of gate seals, service valves, debris clearing, etc.), and special inspections and repair work (e.g., dive inspections, interior inspection of the gate chamber, gate recoating, repair/replacement of drain lines and other piping and valving, etc.).

- Control Systems and Operator Training. Drum gates can be controlled by manually operated or automated control systems. As demonstrated by the incidents above, human error can also contribute to drum gate failure. As such, these systems need to be tested and verified on a regular basis. Furthermore, operators need to be trained and familiar with systems operations and know how to identify problems in programming or issues with sensors. Reservoir level monitoring and rate-of-change alarms can be used to alert operators to unintended gate operation. If safely practical, operators and additional staff can also be stationed at the dam site when storms are forecasted and/or debris accumulation is expected to monitor gate operations more closely.

- Early Warning Systems. Following the 2020 incident at Cleveland Dam, Metro Vancouver has endeavored to improve public warning systems and install additional public warning signage downstream of the dam. In addition, river users and other stakeholders are also being engaged. Given the history of documented, inadvertent releases at dams equipped with drum gates, it is essential that early warning systems are in place to improve safety and reduce risk in the event of a sudden release. These measures can be complemented by an up-to-date Emergency Action Plan as well as close communication with downstream communities and first responders.

Note: Similar lessons to be learned may also be applied to dams equipped with pneumatically-actuated spillway gates or other control features where sudden, instantaneous release may occur.

References

(4) PG&E. (1997). Investigation of Uncontrolled Operation, Highway Side Drum Gate, Cresta Dam. Pacific Gas & Electric Company.

(7) Metro Vancouver. (2020). Metro Vancouver Releases Preliminary Review Findings, Cleveland Dam Event on October 1, 2020 [Media Release].

This lesson learned was peer-reviewed by Russell Bowlus, CA Department of Water Resources, Division of Safety of Dams; Joshua Paquet, Gannett Fleming; and Roy Arnold, Pacific Gas & Electric Company.

Cleveland Dam (British Columbia, 2020)

Folsom Dam (California, 1995)

Additional Case Studies (Not Yet Developed)

- Hoover Dam (Nevada/Arizona, 1941)

- Guernsey Dam (Wyoming, 1986)

- Black Canyon Diversion Dam (Idaho, 1998)

- Cresta Dam (California, 1997)

- Rock Creek Dam (California, 2016)

Appurtenant Structures for Dams (Spillway and Outlet Works) Design Standards

Chapter G-2: Gates Other Than Radial Gates

Federal Guidelines for Dam Safety

Spillway Gate Failure or Misoperation: Representative Case Histories

Water Control Gates: Guidelines for Inspection and Evaluation