Oroville Dam (California, 2017)

Oroville Dam and Spillways

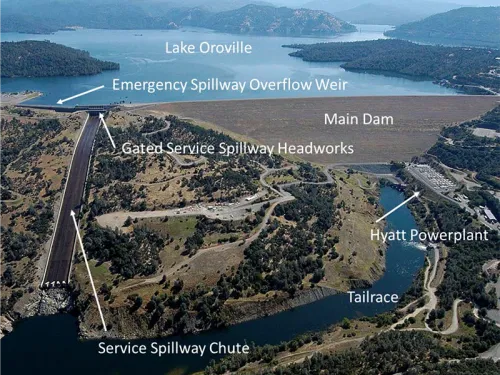

With a height of 770 feet, Oroville Dam is the tallest dam in the United States. Completed in 1968 and located north of Sacramento in the foothills of the Sierra Nevada mountains, this large earthfill embankment dam is owned by the California Department of Water Resources (DWR) and is one of the key features of the California State Water Project, which supplies water to more than 23 million people throughout California and is the largest state-owned water storage and delivery system in the United States. To convey water past the dam, the dam has two spillways on its right abutment. The service spillway consists of a concrete chute which is over 3,000 feet long and 179 feet wide, dropping about 500 feet to the river below, and controlled by eight steel radial gates at its headworks structure. The adjacent unlined emergency spillway has two sections at its crest: a concrete ogee weir which is up to about 50 feet high, adjacent to a broad-crested weir section. Below these crest sections, emergency overflow runs down the hillside over natural terrain to the river below.

Spillway Incident

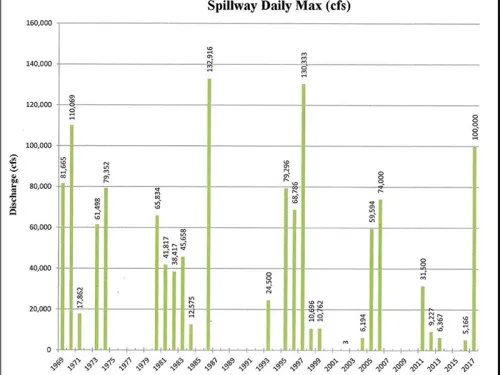

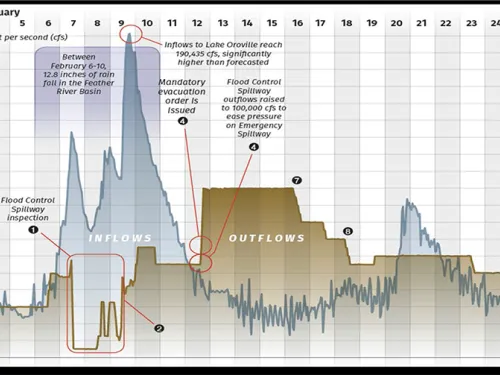

As documented in extensive media coverage, on February 7, 2017, while the service spillway flow was about 52,500 cfs (much less than the historical maximum of 160,000 cfs about a decade prior), the service spillway chute suddenly experienced failure and removal of a section of the concrete slab about halfway down the chute. This was immediately followed by rapid erosion of the foundation and adjacent ground, and progressive failure and removal of the chute slab in the upstream and downstream directions. In an effort to monitor and control the damage to the chute while managing the reservoir level, adjustments were made to the chute flow, but major storms in the large watershed ultimately resulted in the reservoir rising until the crest of the emergency spillway was overtopped for the first time in its history, four days after the chute damage initiated. Despite the maximum flow at the emergency spillway reaching only about 12,500 cfs (less than 4% of its design capacity), staff of the owner and regulators were shocked to see that the hillside was eroding and headcutting rapidly due to the overflow, to the extent of posing a risk that the ogee weir structure at the crest of the emergency spillway could potentially be undermined and fail due to overturning or sliding instability, resulting in downstream flooding due to uncontrolled release of the reservoir. This risk prompted opening of the gates for the service spillway in order to increase the chute flow to about 100,000 cfs and lower the reservoir level, as well as evacuation of about 188,000 people. Due to the very large size of the dam and spillways, and the number of people at risk, this was one of the most serious dam safety incidents in United States history, and the estimated cost for the repairs and recovery was about $1.1 billion.

Forensic Investigation

As the Federal regulator for the Oroville hydropower project, the Federal Energy Regulatory Commission (FERC) required the owner to have an independent forensic investigation conducted, and the owner asked the Association of State Dam Safety Officials (ASDSO) and United States Society on Dams (USSD) to recommend six members for the forensic team. The recommended forensic team was accepted by the owner and FERC, and the team completed its investigation over a period of 9 months, releasing two interim memoranda and a 584-page final report in January 2018. This was the first major investigation of a dam incident in which human factors were given the same level of attention as physical factors. Investigation of human factors enabled identification of underlying reasons for why judgments and decisions were made which resulted in the physical sequence of events which culminated in the spillway failures. The investigation involved reviewing thousands of pages of documents related to planning, design, construction, inspections, and evaluations of the dam and spillways; evaluation of the owner’s organizational structure and culture, dam safety program, and regulatory framework; site forensic inspections; review of extensive post-incident photos, videos, geologic mapping, and forensic test data; engineering analyses; interviewing more than 75 people (many of them multiple times); online surveys; numerous team meetings; and briefings to the media, the owner, FERC, and a United States Senate appropriations committee.

Failure Mechanism and Contributing Human and Physical Factors

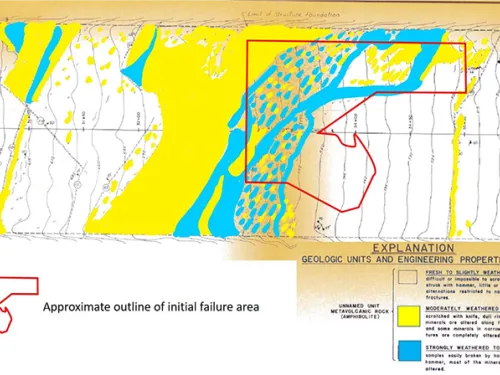

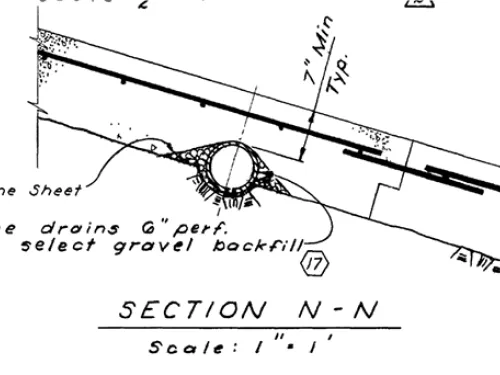

The independent forensic team concluded that the Oroville Dam spillway incident was the result of interactions of numerous human and physical factors, beginning with the design of the project and continuing during the half-century until the incident. The incident was fundamentally the result of a long-term systemic failure to recognize and properly address the deficiencies and warning signs which preceded the incident, and there was no one root cause. This systemic failure involved practices of the owner, its Federal and state regulators, its consultants, and general industry practices in the United States. Therefore, the incident could not reasonably be “blamed” mainly on any one individual, group, or organization. Regarding the physics of the failure, during service spillway operation on February 7, 2017, water injection through both cracks and joints in the service spillway chute slab, likely driven by stagnation pressure, resulted in uplift forces beneath the slab which exceeded the uplift capacity and structural strength of the slab, at a location along the steep section of the chute. The uplifted slab section exposed the underlying poor quality foundation rock at that location to unexpected severe erosion, resulting in removal of additional slab sections and more erosion. This failure mechanism involved inherent vulnerabilities in the spillway designs and as-constructed conditions, subsequent chute slab deterioration, and poor spillway foundation conditions in some locations. The inherent vulnerability of the service spillway design and as-constructed conditions reflected lack of proper modification of the design to fit the site conditions, and almost immediately after construction, the concrete chute slab cracked above and along underdrain pipes, and high underdrain flows were observed. The slab cracking and underdrain flows, although originally thought of as unusual, were quickly deemed to be “normal,” and as simply requiring on-going repairs. However, repeated repairs were ineffective and possibly detrimental. Over time, chute flows and temperature variations led to progressive deterioration of concrete and corrosion of steel reinforcing bars and anchors in the chute slab, with likely loss of slab strength and anchor capacity. There was likely also some shallow underslab erosion, damage and deterioration of the underdrain system, and some loss of underdrain system effectiveness, which contributed to increased slab uplift forces. The particularly poor foundation conditions at the initial service spillway chute failure location likely contributed to low anchor capacity and shallow underslab erosion. The seriousness of the weak as-constructed conditions and lack of repair durability was not recognized during numerous inspections and review processes over the half-century history of the project. For example, although the poor foundation conditions at both spillways were well documented in geology reports, these conditions were not properly addressed in the original design and construction, and all subsequent reviews, including FERC five-year reviews and Potential Failure Mode Analyses (PFMAs), mischaracterized the foundation as “good quality rock.” Following the unexpected chute slab failure and erosion, and subsequent closure of the service spillway gates to examine the damage, difficult risk tradeoff decisions were necessary over the next few days, in the face of considerable uncertainty and differing opinions, in order to manage the incident. Either the gates needed to be re-opened, with the potential for further service spillway damage and/or damage to a power transmission tower, or the lake levels would rise and the emergency spillway weir would be overtopped, with potential for erosion at the emergency spillway. In addition, erosion had transported a tremendous amount of debris into the river channel, and the resulting high tailwater was threatening to flood the powerhouse. The decision-makers attempted to find a “sweet spot” such that the service spillway could continue to be used, but with discharges no greater than necessary to just prevent the lake from rising above the emergency spillway weir. The series of decisions which were made ultimately resulted in the reservoir rising high enough to initiate flow over the emergency spillway weir. Once the emergency spillway was allowed to overtop and the rapid erosion of the emergency spillway was apparent, the evacuation order became a necessary precaution. There were many opportunities to intervene and prevent the initial spillway failure, but the overall system of interacting human and physical factors operated in a way that these opportunities were missed by the owner, its Federal and state regulators, and many consultants hired by the owner during the half-century history of the project. Numerous human factors, including organizational and industry factors, contributed to the physical factors not being recognized and properly addressed, and to the decision-making during the incident:

• The principal designer of the spillways appears to have been a relatively inexperienced engineer and, despite the very large size of the dam and spillways, the design of the service spillway did not fully meet the spillway design best practices of the era

• The owner was generally overconfident regarding the integrity of its civil infrastructure

• The owner took a reactive rather than proactive approach to dealing with civil infrastructure risks; this was fostered by inherent pressures to control costs and deliver water and power without interruption

• The owner, both regulators, and the many consultants paid insufficient attention to the spillways, as compared to the main dam

• The owner’s dam safety program was not sufficiently mature, lacked clear executive-level accountability, and was excessively reliant on regulators and regulatory processes to identify risks

• The owner lacked sufficient staffing resources and technical expertise; this was influenced by governmental and organizational bureaucratic constraints and insularity of the owner’s organization

• The owner’s information management system for its dams was inadequate, resulting in important information sometimes not being in the right hands at the right times

• There were strained relationships within the owner’s organization, particularly between its Operations & Maintenance (O&M) and Engineering Divisions, which inhibited effective communication and collaboration within the organization

• The dam industry in the United States lacked effective and efficient organization and dissemination of technical best practices information for dam engineering and dam safety throughout the industry, resulting in insufficient technical expertise of many engineers and geologists involved in the Oroville Dam project.; these engineers and geologists “didn’t know what they didn’t know”

Lessons Learned

As detailed in the forensic report referenced below, there were numerous lessons learned from this incident for the owner, its regulators, its consultants, and the dam industry in the United States. Most broadly, the independent forensic team concluded that:

“Although the practice of dam safety has certainly improved since the 1970s, the fact that this incident happened to the owner of the tallest dam in the United States, under regulation of a federal agency, with repeated evaluation by reputable outside consultants, in a state with a leading dam safety regulatory program, is a wake-up call for everyone involved in dam safety.”

References:

This case study summary was peer-reviewed by Mark E. Baker, P.E., DamCrest Consulting.

Lessons Learned

A complete and thorough dam record is essential.

Learn more

Concrete-lined spillways are vulnerable to significant damage and potential reservoir breach if flows are not safely contained within the conveyance structure.

Learn more

Dam incidents and failures can fundamentally be attributed to human factors.

Learn more

Dams should be thoroughly assessed for risk using a periodic risk review process including a site inspection, review of original design/construction/performance, and analysis of potential failure modes and consequences of failure.

Learn more

Downstream flooding can be caused by spillway flows that exceed channel capacity or as a result of reservoir misoperation.

Learn more

Downstream of constructed spillway exit channels, spillway outflows can erode and even breach dam embankments and can adversely impact the operation of outlet works.

Learn more

Emergency Action Plans can save lives and must be updated, understood, and practiced regularly to be effective.

Learn more

Floods can occur due to unusual or changing hydrologic conditions.

Learn more

Forensic investigations are needed for major dam failures and incidents in order to determine the history of the contributing physical and human factors, and the culminating physical failure modes and mechanisms.

Learn more

Intervention can stop or minimize consequences of a dam failure. Warning signs should not be ignored.

Learn more

Many earth-cut spillways have been constructed in erodible material that can result in unsatisfactory performance and breaching of the spillway

Learn more

Past successful dam performance does not guarantee future successful performance.

Learn more

Stability of the dam foundation and other geologic features must be considered during dam design.

Learn more

The study of past incidents and failures aids in the assessment of existing dams.

Learn more

Timely warning and rapid public response are critical to saving lives during a dam emergency.

Learn moreAdditional Lessons Learned (Not Yet Developed)

- Physical inspections are necessary, but not sufficient, to identify risks and manage safety.

- Periodic comprehensive reviews of original dam design, construction, performance, maintenance, and repairs are needed for all features of dam projects.

- Compliance with regulatory requirements is necessary, but not sufficient, to manage dam owners’ and public risk.

- Potential Failure Mode Analyses (PFMAs) are useful, but the processes used for performing them can and should be improved.

- Appurtenant structures of dams should receive attention appropriate to their importance and associated risks, and should not be eclipsed by attention to the main dam structure.

- Dam owners must develop and maintain mature dam safety management programs which are based on a strong “top down” dam safety culture with clear executive-level accountability.

- Nationally-recognized best practices related to dam engineering and dam safety should be established and made easily accessible to the entire dam industry.

Best Practices and Risk Methodology Chapter A-3

Best Practices and Risk Methodology Chapter D-1

Best Practices and Risk Methodology Chapter D-2

Best Practices and Risk Methodology Chapter D-3

Best Practices and Risk Methodology Chapter D-6

Best Practices and Risk Methodology Chapter E-2

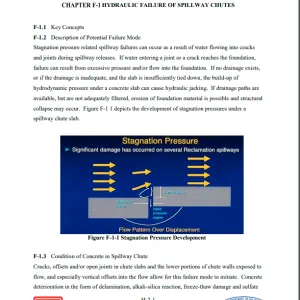

Best Practices and Risk Methodology Chapter F-1

Design Standards No. 14

Independent Forensic Team Report for Oroville Dam Spillway Incident